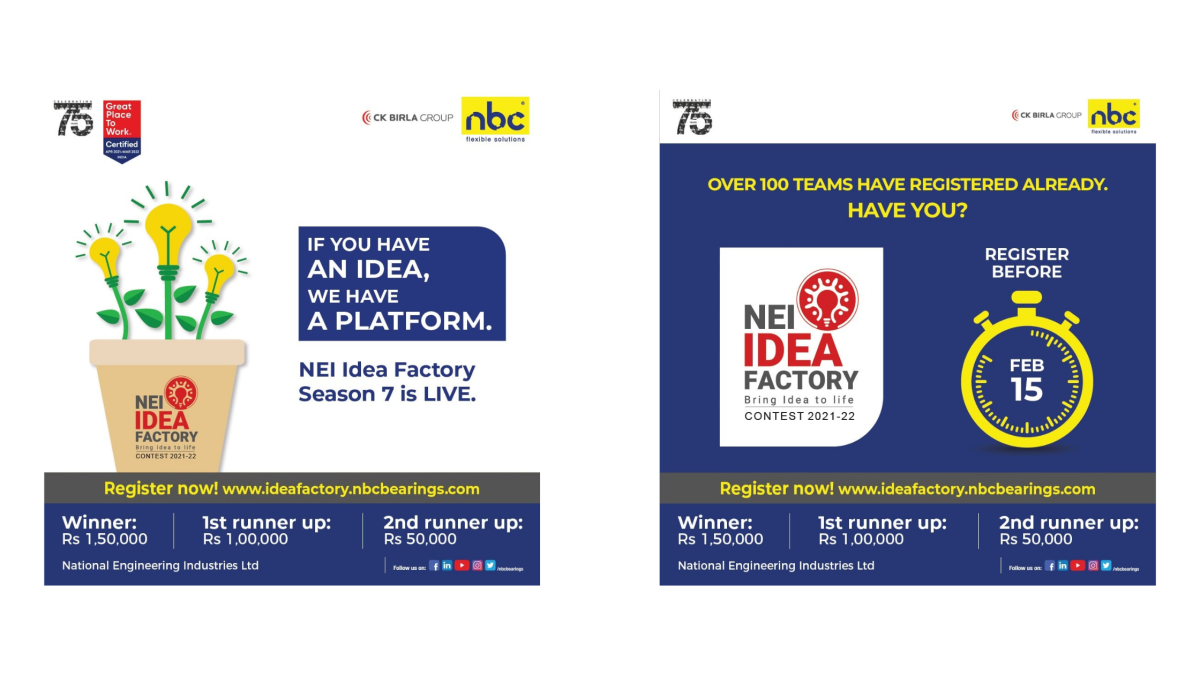

Winning team will get a cash reward of INR 1,50,000. The registrations are open till 15th February

Jaipur, 8th February 2022: National Engineering Industries Ltd. (NEI), part of USD 2.4 billion diversified CK Birla Group is inviting participation for their ongoing 7th edition Idea Factory- the brand’s flagship contest organised for young engineering students. Conducted virtually, the Idea Factory contest aims to inspire and mobilize young minds to innovate out of the box ideas.

Applicants will be able to register for the contest through the official Idea Factory website: https://ideafactory.nbcbearings.com till February 15, 2022.

For achieving the winner title and cash rewards, shortlisted applicants will be put through technical and skill-based tests in the form of quizzes, idea pitch submissions, and virtual presentations. Shortlisted teams will be assigned mentors from NEI who will guide them to nurture their idea. These teams will be judged by NEI’s leadership team on parameters like innovation, suitability of idea and final presentation. The winning team will be presented with a cash reward of INR 1,50,000, followed by the first runners-up receiving INR 1,00,000/- and the second runners-up getting the cash prize of INR 50,000.

Sharing his views on this event, Rohit Saboo, President & CEO, National Engineering Industries Ltd, said, “We are elated and proud to enter the 7th season of NEI-idea Factory. Through this one-of-a-kind contest, we aim to build a legacy of innovation for young disruptive Indian talent. Over the years, we have seen immense talent and creativity shine through our participants. We are confident that this year will be no different.

Recent pandemic has brought uncertainty across various realms of life. New normal demands digital and technological shift for maintaining sustainability in businesses. Over the years technology-led innovations have dominated the business space. We believe the trend will continue, and we will see many submissions and practical usage of artificial intelligence, big data, and machine learning in solving some of the everyday challenges.”

The competition, launched in the year 2015, strives to identify and train young Indian talent. The 6th Edition of the contest saw participation from over 100 teams from Engineering institutes across the country. Of those who participated, 48 teams were shortlisted, with 11 teams reaching the final round.

About National Engineering Industries Ltd (NEI)

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery. Headquartered in Jaipur, NEI is an integral part of the US$ 2.4 bn CK Birla Group. Having started with 30,000 bearings in 19 sizes in 1946, NEI has evolved to manufacture over 200 million bearings each year offered in more than 2300 variants to serve a host of customers across India and 30 other countries across five continents. NEI acquired Kinex bearings in 2020 through its wholly-owned European subsidiary. Leading customers from the US, South Africa, Russia Germany, Brazil, Japan and Australia, etc. have entrusted NEI with their critical product requirements. NEI also serves the Indian aftermarket through a countrywide network of 550 authorized stockists. With an employee strength of over 2,800 and five manufacturing plants in Jaipur, Newai (Rajasthan), Manesar (Haryana) and Vadodara (Gujarat), NEI is equipped with global manufacturing and process technology and is one of the best R&D centres in the country.