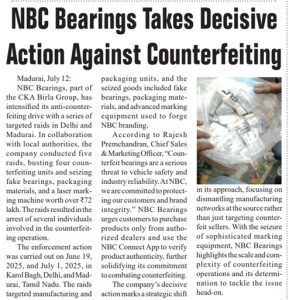

NBC Bearings Cracks Down on Counterfeiters with Major Raids in Delhi and Madurai

Seizes fake bearings and machinery worth over ?72 lakh in coordinated enforcement actionNational Engineering Industries Ltd. (NEI), part of the CKA Birla Group and manufacturer