PRODUCTS

Next Generation Products

NBC Bearings is committed to continuously creating relevant, innovative and effective products for its customers, not just through dialogue and responses to specific needs but by understanding and anticipating trends in industries and technology. This is why increasingly NBC Bearings customers are working with us as partners in development.

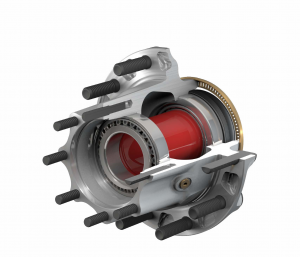

Preset Hub Assembly

NBC has partnered with ConMet of USA to manufacture Pre-Set Hub assemblies for Heavy commercial vehicle applications. Preset hubs utilize pre-adjusted bearings to facilitate proper installation, extend seal and bearing life and ease maintenance. Almost 90% of the heavy trucks in North America use the preset hub technology. A preset hub is a pre-adjusted but serviceable assembly. The individual components of a preset Hub (Seals or bearings) can be replaced as needed. The product offers the right balance between cost, performance & weight for different applications. This technology offers major benefits such as:

- Reduced assembly labor

- Lower maintenance costs

- Elimination of failures due to bad bearing adjustments

- Minimizes risk of assembly damage or incorrect assembly of seals.

Low Torque Bearings

One of the critical areas related to automobiles today is the conservation of natural resources. In a vehicle, only about 12.6 % of energy is used for moving the vehicle whereas 62% is lost to engine friction, engine-pumping losses and to waste heat, 17% is lost in idling, 2% lost in accessories operation and 5.6% lost in the drive train due to friction and slippage.

By understanding the various torque contributors to the bearing such as grease, seal and internal bearing geometry, NBC has developed the low torque bearing technology. The low torque grease has been developed by various fundamentals on tribo-meter along with design of low torque seal and optimization of internal geometry to improve fuel efficiency. Low torque bearings reduce friction by 15-20% and improve fuel efficiency.

NBC has engineered fuel efficient bearing for transmission and wheel bearing application of two wheeler segments. These bearings have also been developed for other automotive segments (cars, trucks, tractors, etc.) Various other programs are underway as well and NBC is working towards extending the technology to other areas.

Sensor Bearings

NBC’s Sensor Bearings are a special kind of bearings in which sensors are integrated within the bearing unit in order to measure the critical parameters like Shaft Speed (RPM), direction of rotation, and temperature. They are compact, reliable, simple and ready to mount. It is an integrated solution provided to the user for greater accuracy and precision, even a slightest rotary motion can be monitored with this bearing.

Features- High speed, low/^que and low noise bearing

- Integrated with sensor capable measure

- Equipped with reverse polarity, over voltage & over current protection protection grade of IP67

EMB Series

EMB Series stands for Electric Motor Bearings. These bearings are used for high speed application. Typical expectations are light weight, low friction, high transient ramp capability, high RPM and low noise. In a typical electric vehicle, an extra 1% of mileage can be gained by using a set of optimized bearings and seals on the electric traction motor and gearbox compared to conventional alternatives.

FEATURES- Fulfill the low noise requirements

- Energy efficient bearings

- Solutions for current leakage issues

- High Speed EMB —Appiication

- High speed electric motors & transmission

- Series Bearings : Planetary gearboxes

- Insulated and conductive bearings for induction motors

Conductive Bearings

Good conductivity is required for upper side bearings of automotive steering for current grounding in the functioning of horn. Conductive bearing contains a circlip wire which is placed in a groove provided on both rings and is held in place by spring force which will fulfill the requirement of passing the current.

Features- Provides electrical conductivity

- Specially designed grooves to hold conductive wire

- Specially designed conductive wire

Hybrid Bearings

NEI has developed Hybrid Bearing as Application another solution to the challenging EV v High speed electric motors & transmission application. Light weight and inertness v__ Insulated bearings for induction motors of the advanced ceramic material reduces centrifugal forces and prevents the current leakage of demanding high-speed application.

Features- High ball hardness

- Current insulation property

- Capable to run in a thin lubrication condition

- Low coefficient of friction at contact

Insuohm Bearings

Electrical insulation coating to prevent electrical pitting in the bearings and hence improved bearing’s life in motor bearings.

Features- Improves bearing’s life in electrical currentpassage

- Optimized coating with plasma spray process

- High insulation resistance

- High dimensional stability after coating

- Easy-to-mount

Oil impregnated Bearings

Oil impregnated bearings composed of 70-80% of lubricating synthetic oil. Oil is moulded and solidified with Application polymer to form a casing which acts as a lubricant reservoir throughout bearing’s life.

Features- Improved lubrication system with consistent lubricant supply

- Superior lubricant — synthetic oil

- Lesser torque due to no churning phase

- Excellent performance in water and dusty environment due to inherent sealing property

- Environment-friendly molding process

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

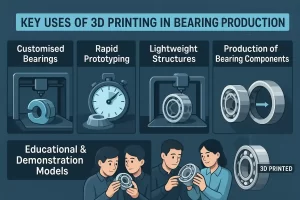

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

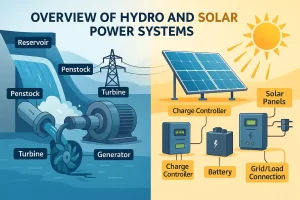

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

The Critical Role of Bearings in Drones and UAVs

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Request more information

Leadership quotes