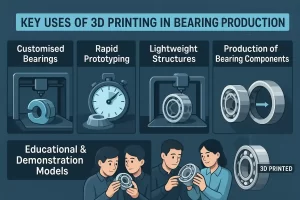

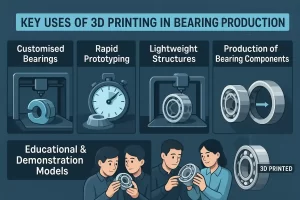

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Toll Free: 1800 3000 6222

Telephone: +91 141 222 3221

Fax: +91 141 222 1926, 222 2259

CIN: U29130WB1946PLC013643

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

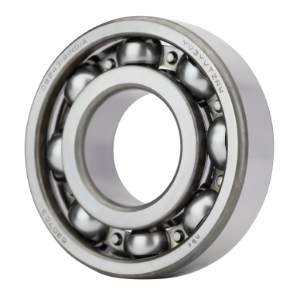

One of the most significant components of all machines and even most household appliances is a ball bearing. It helps connect two machine components, which move relative to one another, in a smooth and frictionless motion. While there will be friction on the surface contact area, the same will not disrupt the operations of the machinery. In real life applications of ball bearings it is observed that one component will be a rotating shaft while the other will have a fixed housing.

Ball bearing is not a single component, but an assembly of different components. Primarily there are four main parts in any ball bearing.

These races have different diameters: the smaller one fits inside the larger, and the metal balls fill the space between them which can be restrained and separated using a retainer or cage. Their low friction rotary motion provides smooth operation, high performance and efficient weight management due to their spherical shape.

Ball bearings are almost everywhere. You would be surprised to know how many industries are running on ball bearings.

The basic principle of ball bearings is to reduce friction between two moving surfaces by replacing sliding friction with rolling friction.

A ball bearing device is a mechanical component used to support rotating shafts or axles while minimizing friction and allowing smooth movement. It consists of

Ball bearing devices are commonly found in various applications, including automotive, industrial machinery, household appliances, and aerospace systems.

Ball bearings are commonly made from high-quality alloy steels, such as chrome steel or stainless steel, which offer excellent strength, hardness, and corrosion resistance.

These materials are chosen for their ability to withstand high loads, shock loads, and harsh operating conditions while maintaining dimensional stability and wear resistance.

Ball bearings are used by a wide range of industries and applications, including automotive manufacturers, industrial machinery builders, aerospace engineers, and consumer electronics manufacturers.

They are found in everyday items such as cars, bicycles, washing machines, electric motors, and computer hard drives, where smooth and efficient rotation is essential.

Ball bearing size refers to the dimensions of the bearing, including its bore diameter, outer diameter, and width. These dimensions are standardized according to international standards, to ensure compatibility and interchangeability between different bearing manufacturers. Ball bearing size may vary depending on the specific application and load requirements.

Ball bearing radius refers to the curvature of the inner and outer races of the bearing, which determines the contact area between the balls and the races. The radius of curvature is carefully designed to ensure smooth and efficient rotation of the bearing while minimizing stress concentration and wear. Proper bearing radius design is critical for achieving optimal performance and longevity in various applications.

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Copyright © 2023 NEI Ltd. All rights reserved.

Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary.

E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy