Services

Condition Monitoring Services

The promise of simpler means to assess machinery and optimize the operations.

Every machinery requires thorough maintenance and foresightedness for the highest efficiency. In order to predict potential failures to improve asset reliability, Condition Monitoring is considered to be a trusted perspective technique at NBC.

The market today demands products of the highest quality with negligible defects. Therefore, it is essential to adopt a system that enables the machine to operate within vibration tolerances and in turn allows optimal productivity and faultless process.

We, at NBC Bearings, provide intelligent solutions for Condition Monitoring in order to improve assets reliability. Our expertise in various streams of Condition Monitoring helps industries to maintain their assets failure-free. With the intention to proactively work towards avoiding failure, the scope of CMS largely consists of:

- Vibration analysis

- Lube oil analysis

Uncontrolled vibrations create undesirable behavior in machinery that leads to catastrophic failures. Condition Monitoring has many benefits that can increase the scope of efficiency. Some of those benefits entail:

Increased profits

- Cuts downtime and parts inventory

- Improve overall quality

Boosts productivity

- Improves the assets’ reliability

- The prediction of the remaining useful life of assets

Allows the use of the exact permissible life of assets

Major bearing application areas

Vibration Signature analysis is the process by which intelligent information is extracted about the condition of a machine through the vibration data gathered during machine operation. NBC Bearings perform fault diagnosis based upon vibration signature and predict various machinery faults. Our expertise in vibration analysis and fault diagnosis provides intelligent solutions for protecting machinery from catastrophic failures.

Alignment practices are often required to protect equipment from premature failures. Misaligned conditions of assets often lead to more power consumption, severe vibration levels, and premature bearing failures.

Our expertise in laser alignment offers alignment solutions to industries. We offer field laser alignment, which makes the alignment process fast and accurate by avoiding a trial and error method.

We perform laser alignment for the shaft in coupled & uncoupled condition, torsion shaft alignment, ID and FD fan alignment, cooling tower fan shaft alignment, windmill alignment, cardan shaft alignment, soft foot correction and thermal growth compensation.

The unbalanced condition of the machine is one of the most common contributors to vibrations in rotating machines. If unbalance remains uncorrected, it may lead to severe vibration problems, premature bearing failures, the low performance of machines than expected, and more power consumption.

We offer the highest balancing grade by measuring phase very precisely using the latest FFT data collector and laser-based optical phase reference.

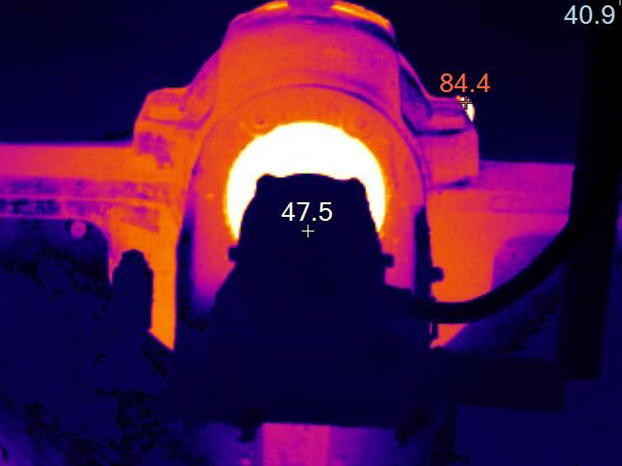

Infrared thermography is a technique that produces a visible graph or a thermographic image of thermal energy radiated by objects.

Thermography often required to detect hot and cold spots, Condition Monitoring of insulation lining of the boiler, steam pipeline and hot air ducts. Detection of thermal abnormalities is also performed using thermography.

We offer thermography services for all critical equipment.

A complete smart solution to protect critical assets from failures through Condition Monitoring is our prime objective. High-end equipment with an advanced method of analysis is the key differentiating element of our service.

For more details and CBM services, please get in touch with us.

Condition Monitoring Products

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

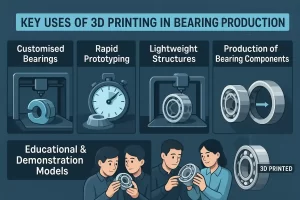

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

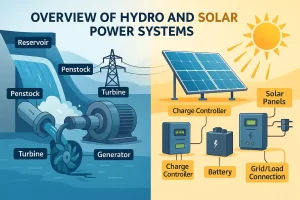

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

The Critical Role of Bearings in Drones and UAVs

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Request more information

Leadership quotes