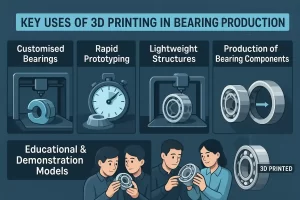

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Toll Free: 1800 3000 6222

Telephone: +91 141 222 3221

Fax: +91 141 222 1926, 222 2259

CIN: U29130WB1946PLC013643

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

Roller bearings are the most significant variety of bearings with a very large number of industry specialised variants. It is known for its typical features which help scale growing industrial needs:

This category encompasses various types, each tailored for specific applications, making them indispensable to cater to diverse industrial needs.

Roller bearings are the backbone of machinery, contributing to the efficiency, reliability, and longevity of various applications across industries. Their diverse types and advantages make them a cornerstone in the world of mechanical engineering, ensuring the smooth operation of countless systems worldwide.

Yes, roller bearings, including cylindrical, tapered, and spherical roller bearings, can take axial loads in addition to radial loads.

The invention of the roller bearing is credited to Swedish engineer Sven Wingquist. Wingquist’s innovative design, which replaced traditional sliding bearings with rolling elements, revolutionized the bearing industry and paved the way for modern roller bearing technology.

The choice between ball bearings and roller bearings depends on the specific requirements of the application.

Roller bearings play a crucial role in machinery and equipment by

Roller bearings are essential components in various industries, from automotive and aerospace to manufacturing and construction, where reliable and efficient operation is paramount.

Roller bearings are commonly made from high-quality alloy steels, such as chrome steel or bearing steel, which offer excellent strength, hardness, and fatigue resistance. These materials are chosen for their ability to withstand high loads, shock loads, and harsh operating conditions while maintaining dimensional stability and wear resistance.

Roller bearings are sized based on their bore diameter, outer diameter, and width dimensions, as well as other design specifications such as load ratings, speed ratings, and clearance values. These dimensions are standardized according to international standards, such as ISO and ANSI, to ensure compatibility and interchangeability between different bearing manufacturers. Additionally, roller bearings are classified into various types and series based on their design, configuration, and intended application.

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Copyright © 2023 NEI Ltd. All rights reserved.

Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary.

E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy