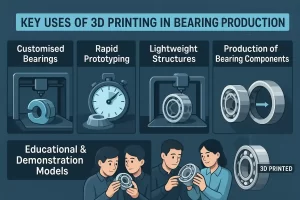

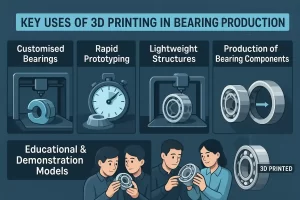

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Toll Free: 1800 3000 6222

Telephone: +91 141 222 3221

Fax: +91 141 222 1926, 222 2259

CIN: U29130WB1946PLC013643

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

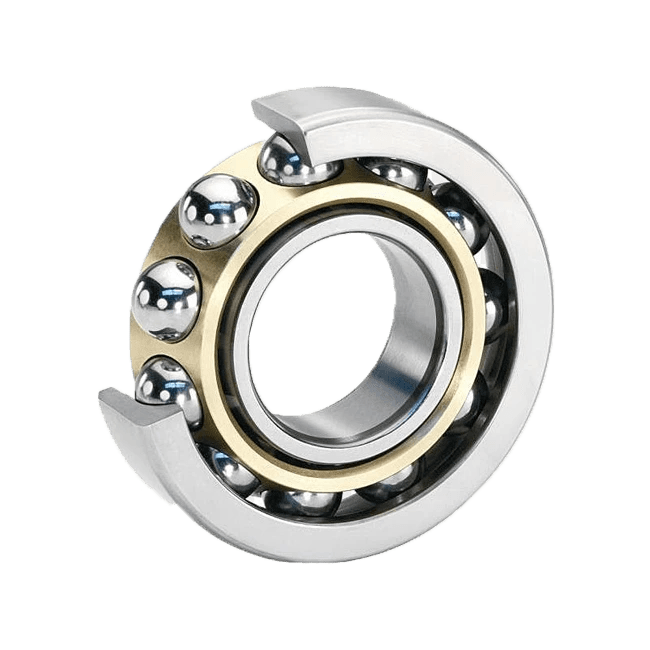

Angular contact ball bearings are a unique variety of bearings. These are designed for combined loading, i.e., it includes radial and axial loading. These are rolling-element bearings which use a roller or a ball to carry the weight of the load.

As the name suggests this has a specific angular contact with the bearing raceway and shoulder. This supports higher axial loads effectively. The bearings are also supported by corrosion resistant coatings, high quality bearing cages and special lubricants to ensure superior performance.

Variations based on number of rows:

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Copyright © 2023 NEI Ltd. All rights reserved.

Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary.

E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy