About us

Supplier Excellence

NEI Supplier partnerships rest firmly on a shared commitment to achieving excellence in quality. Supplier selection is an intensive four-step process:

- Selection assessment

- Technical approval,

- Commercial approval

- PPAP approval

Only those Suppliers achieving more than 80% selection assessment rating are chosen for parts supplies.

NEI’s entire supply chain has a ‘Zero Defect’ approach. Suppliers are measured for quality performance at three levels: Receiving rejection, Shop Rejection and Customer rejection. All suppliers are evaluated every quarter against 8 quality parameters and are awarded performance rating.

DOL Program – NEI encourages it’s ‘A’ grade suppliers to move into Direct on Line (DOL) level which is a recognition for best quality consistency & reliable supply. The DOL suppliers go through a rigorous & stringent 9 months training, assessment & performance evaluation program.

Supplier End TQM and Six Sigma support – We provide quality training, world class consultancy along with sharing of best business practices to our suppliers to percolate excellence practices in their system as well. Every year we encourage them to participate in national level forum such as CII/QCI/TQMI to win awards in various categories related to lean and six sigma practices

Supplier Satisfaction Survey – Suppliers make essential contributions to the total results of the NEI as a whole. There is every reason to anticipate the pressure on increasing the flexibility and efficiency of the operation of the whole value chain through continued engagement with our supplier partners. To understand the need of our suppliers as well supplier satisfaction survey is carried out every year with the purpose to measure the quality of the relationship between supplier and their views about the NEI.

Annual Suppliers Meet – Interactive sessions where our suppliers have opportunity to meet and interact with our OEM partners to ensure quality deliveries. We have also introduced a Rewards & Recognition program to acknowledge and build stronger relationships with our suppliers.

With Happy Customers

If you want to be our supplier kindly fill your details in this form.

To download Supplier Quality Manual 4th Edition

Training on VDA , APQP , 4M Change Management & Customer Specific Requirement

Knowledge sharing with Suppliers

Awards & Recognition

Vision Sharing and Commitment taken from supplie

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight,industry trends, tip news headlines.

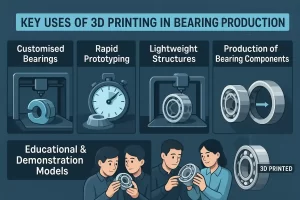

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

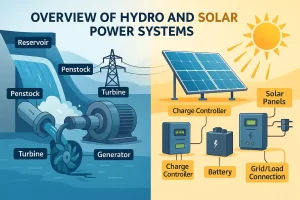

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

The Critical Role of Bearings in Drones and UAVs

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.