Electric Motor Ball Bearings: How they Power Electric Motors

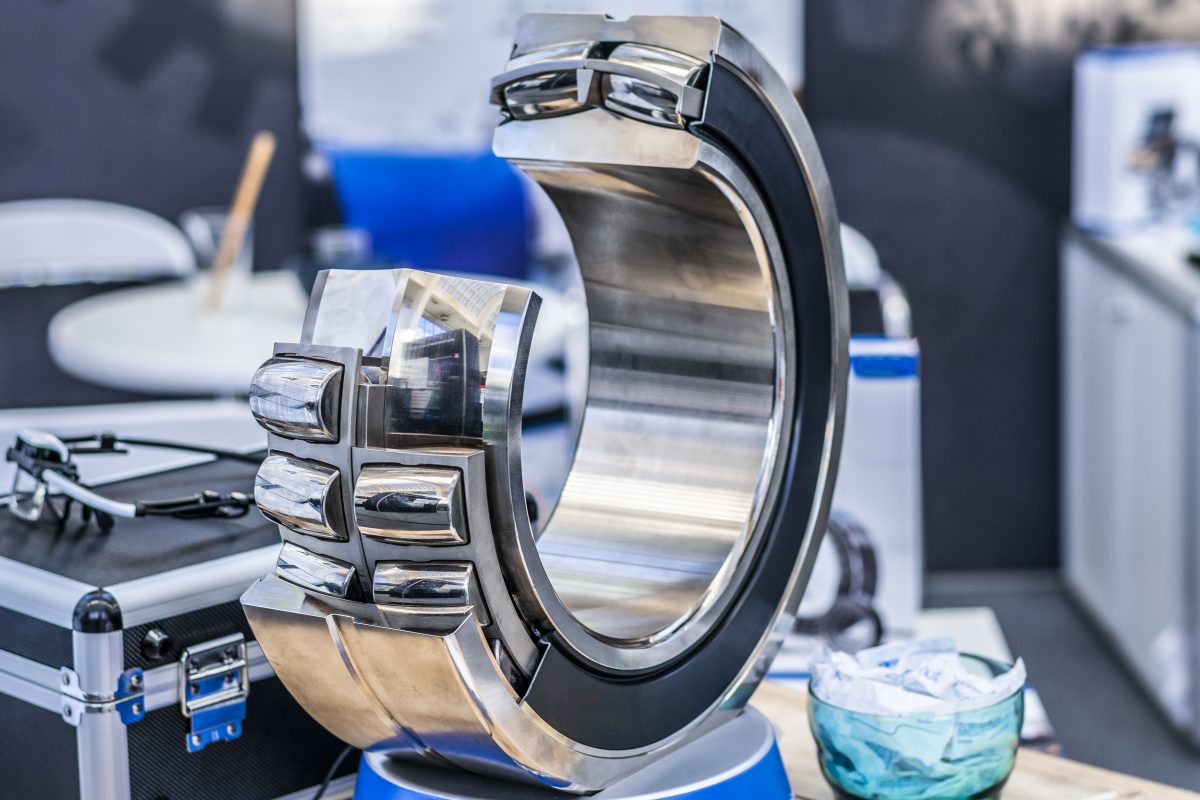

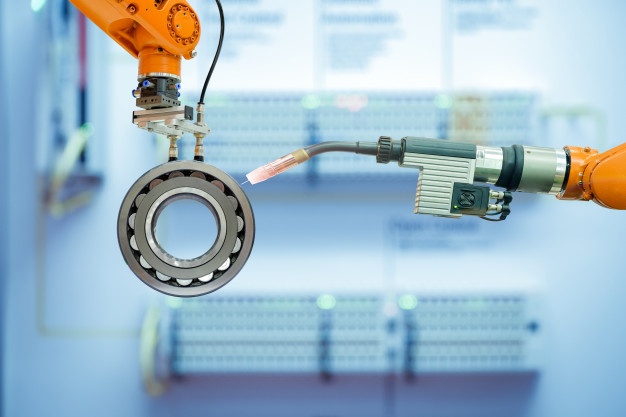

Electric motors require reliable solutions to work in an optimum manner. In terms of mechanical characteristics, electric motors are powerful and versatile, making them useful to work in high-performing machinery. Be it machines at the factory or electric vehicles, these bearings can be used in any of the electrical motors to allow rotary motion and transmit the power to make various parts of the machinery function well. The bearings that support these motors need to allow for smooth, quiet operation while providing key features such as high load capacity, long life spans, and low running noise. Electric motor ball bearings are subject to a variety of forces, including radial and thrust loads, as well as vibration and shock. To withstand these forces, bearings must be carefully designed and manufactured. The most common material used for electric motor ball bearings is steel, but other materials such as ceramic or plastic may be used in some applications.Use Case in Real-Time Scenario

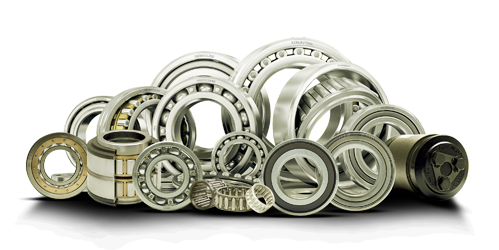

The main performance characteristics of electric motor bearings are high load capacity, high-speed operation, high precision positioning, low noise, etc. They are used in the load and speed requirements of the motor. In terms of general applications, they are widely used electronic appliances, large-scale machinery in factories, electric vehicles, railways, wind turbines, etc. Since these machines have different requirements, various types of bearings are used in different scenarios to power them:- Ball Bearings: These are mostly used in non-belted and direct-coupled applications where the motor runs under 150 horsepower speed. Ball bearings are designed specifically to handle both axial and radial loads in varied conditions within the machinery systems. The most common application of these types of electric motor bearings is in AC motors.

- Standard Roller Bearings: These kinds of roller bearings are designed for belted applications and are perfect for radial loads. They are not used to handle axial loads. It also works with motors that operate at a minimum of 150 HP.

- Angular Contact Ball Bearings: These kinds of electric motor bearings are perfect for high-speed rotating applications with axial loads. It can be configured with different types of cage designs and rows.

- Cylindrical Roller Bearings: These roller bearings are perfect for handling extremely high axial loads. Cylindrical roller bearings work efficiently at both medium and high speeds and support several design alternatives as per the mechanical applications. These are mostly used for belt or gear-driven electric motors.

- Deep Groove Ball Bearings: These ball bearings are a perfect match for electrical motors as it is apt for high-speed applications supporting moderate-type axial and radial loads.

- Sealed Bearings: These are specially designed bearings that work in contaminant-prone environments. However, they have a limited life span as they cant be re-lubricated.

- Shielded Bearings: Shielded bearings are specially designed to protect electric motors from dust, dirt, and other debris. They are made with a metal shield that covers the bearing, preventing contaminants from entering and damaging the sensitive components.