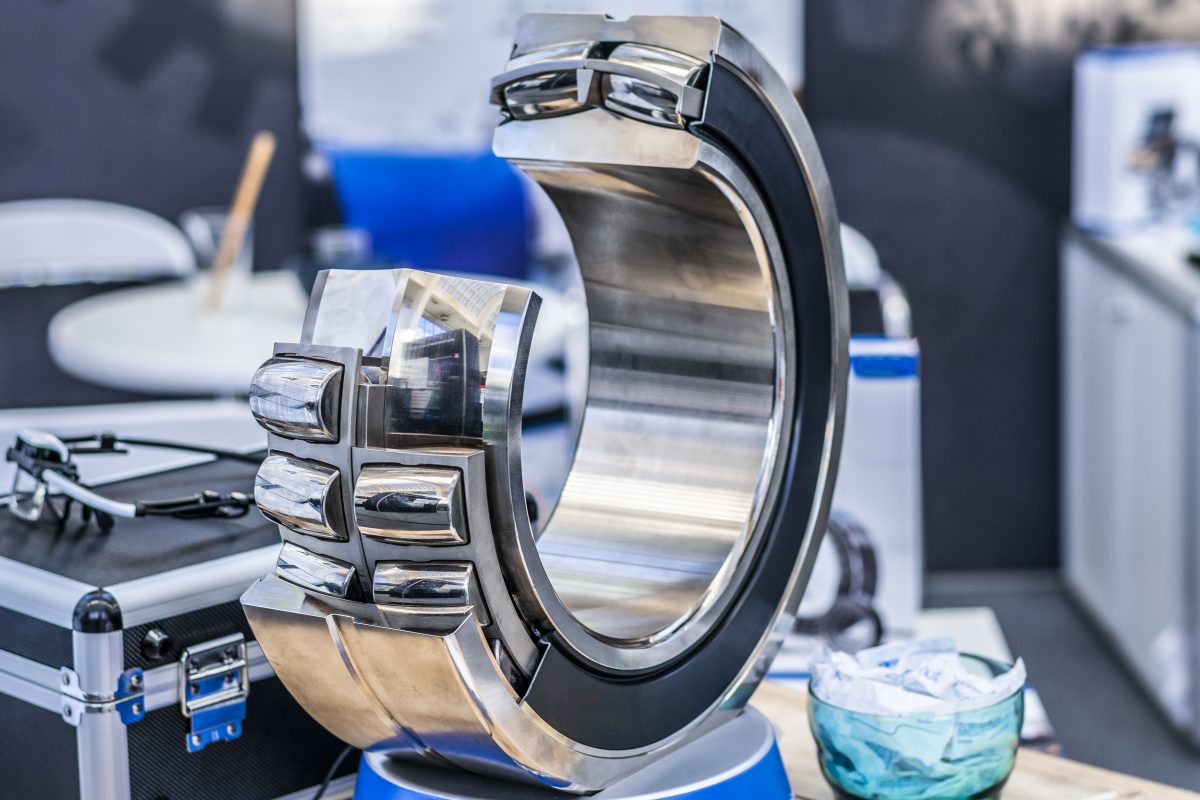

Uses of Cylindrical Roller Bearings

The cylindrical roller bearings can be used in various types of mechanical systems. The different types of cylindrical roller bearings can offer different usages:- Axial Displacement: The bearings are designed to support axial loads and facilitate movement to and from axial directions within the machinery. The N and NU types of cylindrical roller bearings are perfect use cases for axial displacement, as single-row cylindrical roller bearings offer the scope of axial displacement in some limits relative to the housing.

- Withstand Incidental Thrust Loads: The thrust load is a load that is applied parallel to the rotation of the axis. The NF, NJ, and NUP series of cylindrical roller bearings are designed in such a way as to withstand incidental thrust loads apart from radial loads.

- Uses in Heavy Machinery and extreme systems: The cylindrical roller bearings are used in high-speed systems and can be deployed for high-performing systems such as agricultural machinery, wind turbines, mining machines, etc.

Advantages of Cylindrical Roller Bearings

The performance and design are why cylindrical roller bearings are suitable for specific applications. It offers varied advantages, which are as follows:- It has a higher resistance to fatigue and shock than a ball bearing.

- It Offers simple mounting and dismounting due to its unique design.

- It is designed to take the combined radial load (N and NU type) and thrust load (NJ and NUP type).