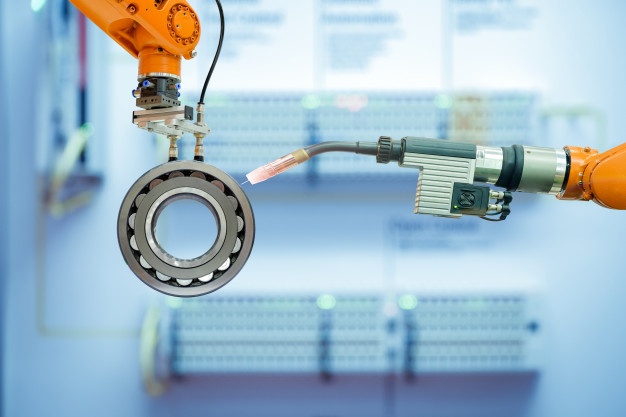

Design of Roller Bearing – Supporting Heavy Machinery

Roller Bearing helps in support the large radial and axial loads in heavy-duty machinery. This works in one direction to guide the axial loads while complimenting bearings are also used simultaneously to support the load in other directions. These types of bearings can be widely used in those conditions where the temperature may vary between -30 degrees celsius to 120 degrees Celsius.Applications of Roller Bearings in Heavy Machinery

There can be varied types of Heavy Machinery that might require heavy-duty applications. Here are some of the applications of roller bearings in heavy machinery:- Wind Turbine Generators for Energy Generation – Wind Turbine generators are usually installed in high-altitude areas which require a reliable bearing solution that can operate within the high-performance wind turbines in high-speed winds. In such conditions, the tapered roller bearing and spherical roller bearings can be installed in the main shaft of the wind turbine that receives the force and can pass on the rotation to the generator.

- Use of Roller Bearing in Agriculture Machinery – The agriculture industry also demands heavy-duty machinery as it has to deal with heavy-duty applications on a day-to-day basis. While these applications range in a multitude of high-performance tasks, the bearings must be reliable and long-lasting as they have to be used in heavy dirt and mud conditions which might also impact the bearing life. The roller bearings are one such perfect solution that can be used in varied tasks which might require heavy radial or axial loads and they can get the work done with ease. The common type of bearing used in the agriculture industry is a tapered roller bearing.

- Construction and Heavy Machinery – The construction industry requires varied earth-moving equipment for a high range of heavy-duty tasks. While there can be varied challenges while dealing with the applications of construction, the bearings are usually exposed to excessive working conditions as machines have to be deployed for high-performance tasks. In order to meet this demand, there is a need for different types of roller bearings such as spherical roller bearings, tapered roller bearings, cylindrical roller bearings, etc. which are designed to deliver the desired performance.

- Use of Roller Bearings in Railways – The railways are considered one of the most reliable modes of transport worldwide. While there are different systems, trains, and tracks connected over wide networks, heavy-duty machines are used to facilitate day-to-day operations. The bearings in the railway industry are used in traction motors, drive units, wheel axles, etc. While the bearings have to work in extreme conditions of carrying heavy loads and adapting to high vibrations in drive units, varied roller bearings like tapered and spherical roller bearings are also widely used to support the mechanical system. Since the railway network is now moving towards high-speed trains, the roller bearings are also designed especially for double helical gears which can work for a longer duration without the need for lubrication.

- Use of Spherical Roller Bearings in Marine Propulsion – Marine propulsion can be referred to as a thrust system that is used to move a boat or a giant ship. While this is also considered in the category of heavy-duty application, the diesel engine of the ship is linked to the propeller which facilitates the movement through a complex system. Here, roller bearings can be used within the shaft or different mechanical systems as there can be conditions where the bearing has to adjust to radial or axial load while also complying with the scope of heavy misalignment. These kinds of bearings are designed to handle one-directional axial load and radial load at the same time while allowing shaft misalignment.