There are different types of bearings available in the market depending on the usage of the product. Needle roller bearing is widely used in many industries such as mining, automobiles, railways, aerospace and many others. This blog will provide all the information about these bearings and will help you to choose the right one for your requirement.

Needle Roller Bearing is one of the economical bearings offering high load capacity due to their special design featuring rolling cylinders with small diameters held between a single race and shaft of a bearing. It also reduces the friction of rotating surfaces making it highly durable. In terms of design, these types of bearings are quite light and small making them fit in those applications which require lesser space. This is a popular type of cost-effective and efficient bearing used by design engineers due to the various technical benefits offered by it.

A needle roller bearing has a diameter to length ratio of between 0.1 and 0.4, measured on the outside of the rollers.

Structure of Needle Bearing - Types of Needle Roller Bearing

There are 4 main types of needle roller bearings, including caged wheel, drawn cup, precision race wheel and thrust wheel. Their typical structure includes an inner wheel or just a shaft to anchor the part, a cage to hold all of the rolling elements within their various compartments and an outer ring. Selecting the right type of needle roller bearing for your specific application depends on a variety of factors such as the necessary load capacity, load type (roller angle), and speed (rpm), as well as the expected temperature limits (typically higher than normal rolling element bearings like ball or sleeve).

Features of Needle Roller Bearing

The Needle Roller Bearings have varied advantages over other types of bearings which are quite larger in size and may not offer the benefits as needle roller bearings offer. The first benefit is that it has a higher load capacity than other bearings. Another advantage it offers is that it delivers the durability to handle the high rigidity of the shaft based on varied types of applications.

Applications Of Needle Roller Bearings

- Needle roller bearings can be used in various types of machinery such as automotive power transmission systems, two and four-stroke engines, planetary gear sets, and air compressors.

- Needle roller bearings are especially useful in machinery that requires high temperature, large load, durability, and quiet operation. As the name implies, the rollers are needle-shaped with a wide diameter at one end and a narrow diameter at the other.

- Needle roller bearings are made of high strength steel with rows of rollers all sharing the same axis. The rollers are supported by the shafts to prevent them from moving in all directions except through the shafts’ axis. The rollers are attached to the shafts by means of cage assemblies.

Conclusion

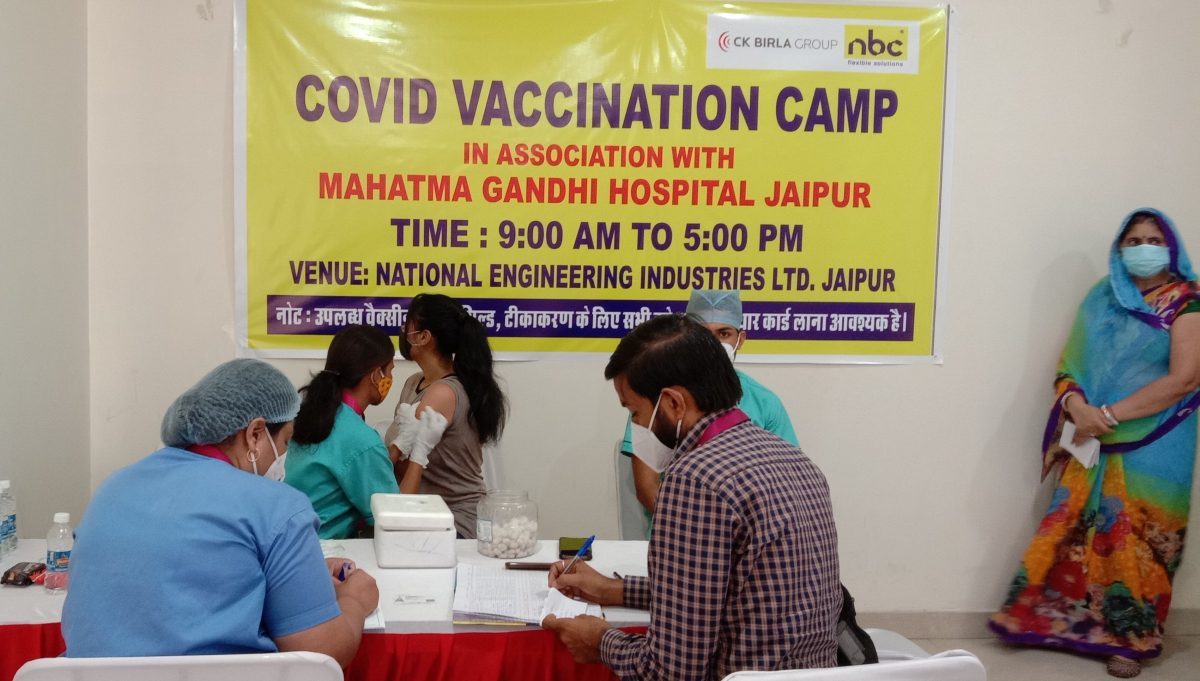

NBC Bearings is one of the leading manufacturers offering industry-standard manufacturing of needle roller bearings. As they have a high industrial demand in varied sectors, it is made with utmost quality and precision to support the working of various mechanical systems.