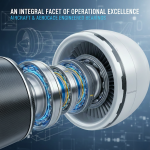

Powersports refers to motorised vehicles used for motorised vehicles used for recreation or competition. These vehicles are fitted with high-performance engines as they need to handle tough terrains and extreme conditions. Though these big and high-performance engines play a key role, a lot of supporting systems and components work together to bring out the full potential. A key component that plays a vital role is the high-speed bearing. These bearings are specifically designed to work under high-speed conditions.

These bearings are crucial for the engine’s performance, ensuring smooth rotation even at high speeds. They’re specially crafted to handle the tough demands of powersports applications, allowing for seamless rotation at high RPMs while also withstanding extreme stress and heat.

Standard bearings are not the recommended/used in high-performance engines or powersports engines to several reasons including:

- Increased Friction: Using a standard bearing in high-performance engines can lead to excessive friction & potential seizure as these engines produce more head and friction than standard engines.

- Material Limitation: Standard bearings are not made of strong material or are heat resistant as high-performance bearings. Thus, it can lead to premature wear and failure.

- Lubrication Issues: Standard bearings may not be able to handle lubrication requirements of a performance engine and it can lead to friction, wear, and failure.

- Low Performance: Standard bearings are not designed in a way to bear the extreme operation stress. They may wear out quickly or fail resulting in decreased performance and reduced power output.

Specially made speed bearings are installed in performance engines to provide the strength accuracy and longevity necessary for seamless operation. Using a standard bearing in these engines can definitely be a recipe for disaster.

Benefits of Using High-Speed Bearings in Racing & Powersports

When it comes to racing and powersports all we tend to imagine is extreme speed, roaring engines, adrenaline-pumping speed, and machines pushed to their absolute limits. Though this is all true, a crucial role is also played by components fitted including the precision-engineered bearings. These bearings are unsung heroes that have an impact on performance, reliability, and efficiency.

The key benefits of using high-speed bearings in racing & powersports includes:

- Support Extreme RPMs: High-speed bearings are specifically designed to handle ultra-high speed without failing. These bearings are usually fitted in engines, gearboxes, and other components spinning at 10,000+ RPMs.

- Heat Resistance: High-speed bearings are made from advanced materials and coatings tolerate higher operating temperatures. These bearings also include advanced cooling features or made from materials that dissipate heat faster.

- Reduced Friction: High-speed bearings are crafted from low-friction materials that minimise energy loss, allowing for more power to be transferred to the wheel. This ultimately leads to improved performance.

- Better Stability: High-speed bearings maintain tight tolerance at extreme speed leading to smoother operation, better handling, and less vibration.

- Lightweight Design: Ceramic or hybrid materials are commonly used in high-speed bearings. Ceramic or hybrid made bearings provide the bearing the strength it requires to cater extreme conditions without excess weight.

Types of High-Speed Bearing

Various types of bearings are designed to handle the intense demands of high performance engines.

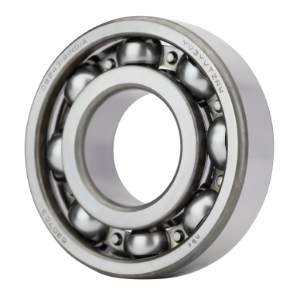

High-speed ball bearings are known for their ability to provide low-friction rotation, even at very high speeds. Ball bearings are generally fitted in gearboxes, electric starters, turbos, crankshafts and various other components in racing and powersports engines.

Roller bearings, such as needle roller bearings and tapered roller bearings, are widely utilised in powersports engines. These bearings manage heavy loads and absorb vibrations effectively.

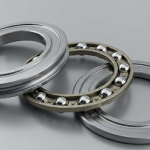

Thrust bearings are prominently used in powersports engines, especially in clutches and crankshafts. These bearings are manufactured in a way to absorb axial forces and ensure the crankshaft stays properly aligned.

Ceramic bearings are most widely used in powersports engines. These bearings are preferred as they are extremely lightweight and have heat resistant properties. Ceramic bearings are fitted in turbos, wheel hubs, and other high-speed rotating parts.

Selection of Right High-Speed Bearings

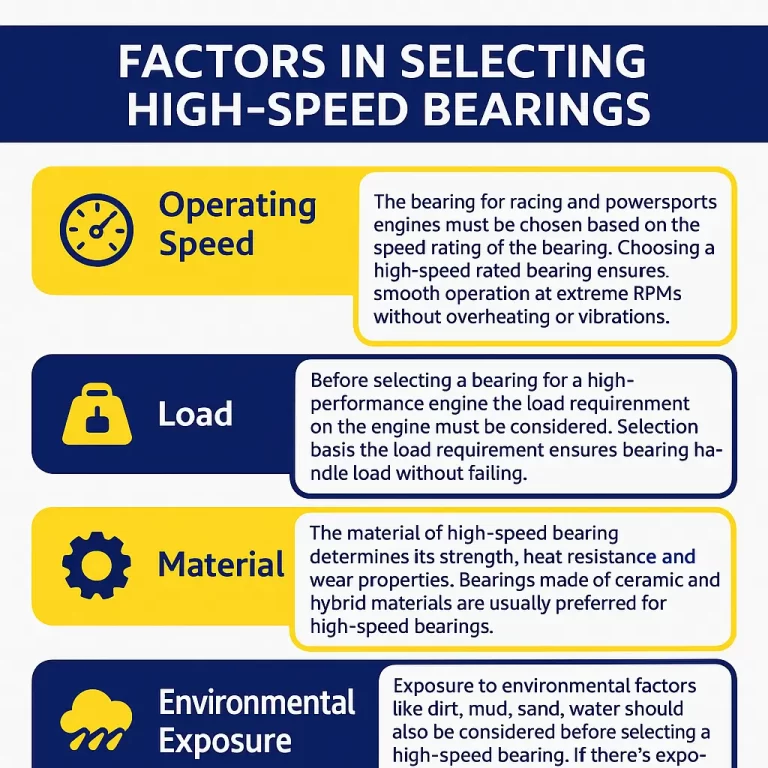

Finding the right type of bearing for powersports and racing engines is important as a mismatch can cause faster wear, lower output and failure. A high-speed bearing must match the engine’s load, speed, environment, and lubrication system. There are several factors to consider when it comes to selecting the right bearing for high-performance engine including:

- Operating Speed: The bearing for racing and powersports engines must be chosen based on the speed rating of the bearing. Choosing a high-speed rated bearing ensures smooth operation at extreme RPMs without overheating or vibrations.

- Load: Before selecting a bearing for a high-performance engine the load requirement on the engine must be considered. Selection basis the load requirement ensures bearing handle load without failing.

- Material: The material of high-speed bearing determines its strength, heat resistance, and wear properties. Bearings made of ceramic and hybrid materials are usually preferred for high-speed bearings.

- Environmental Exposure: Exposure to environmental factors like dirt, mud, sand, water should also be considered before selecting a high-speed bearing. If there’s exposure to dust, dirt, mud, sand, etc a sealed, corrosion-resistant, or coated high-speed bearings should be preferred.

Installation of High-Speed Bearings

Installation of high-speed bearings must be done with accuracy to allow a good fit, alignment, and avoid premature failure. The key to installation is having the right tools and following the manufacturer’s recommendations. There are a number of ways the bearings can be fitted. Different techniques of installation depends on the type of bearing and installation location such as press fit installation, thermal expansion installation, slip fit installation, among others.

- Preparation: This is the first step in the installation and involves cleaning the work area including bearing housings, shafts, and surrounding surfaces.

- Inspection: The second step involves inspecting the fitment areas and checking the shaft and housing to ensure exact fit within manufacturer tolerances.

- Installation: Post cleaning and inspecting the area the high-speed bearing can be precisely installed. The bearing can be installed through several techniques including press fit installation, thermal expansion installation, etc.

- Lubrication & Coating: Post fitment lubrication should be applied before assembly. High-speed bearing grease or manufacturer recommended lubricant should be used.

- Alignment: The step involves checking the bearing’s seating and alignment, misaligned bearings can lead to uneven loading and heat buildup.

- Post-installation Run: During the post-installation run listen for any unusual sounds, check for oil pressure and leaks.

The Role of Lubrication in High-Speed Bearings

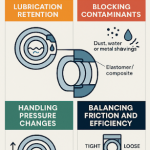

Lubrication is crucial for high-speed bearings, it helps prevent wear, reduce friction, and dissipate heat. Periodically lubricating high-speed bearing also contributes to performance by ensuring smooth operation and maintains bearing’s integrity especially in high-speed application. Some of the benefits of lubrication includes:

|

Role of Lubrication |

Impact |

|

Reduced Friction |

Periodic lubrication or lubrication as per manufacturer guidance minimises metal to metal contact & reduces wear. |

|

Heat Dissipation |

Adequately lubricated high-speed bearing prevents overheating & bearing failure. |

|

Corrosion Protection |

Applying lube coats the surface & prevents oxidation leading to enhanced durability in harsh conditions. |

|

Protection During Startup |

Lubrication protects against dry friction during engine start reducing early wear. |

|

Support Load Capacity |

Properly lubricated bearings helps distribute engine loads evenly & handle dynamic loads. |

Lubricants for racing & powersports engines must be chosen based on compatibility with the engine type, as it is important for optimising engine performance and longevity in racing. Synthetic lubricants, racing specific lubricants, or manufacturer recommended lubricant should ideally be used.