327/700

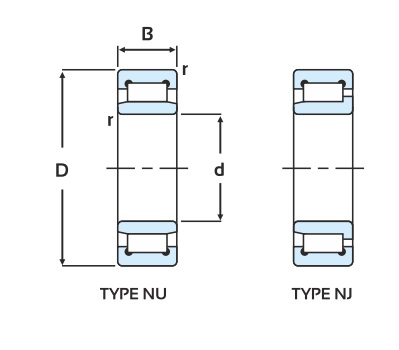

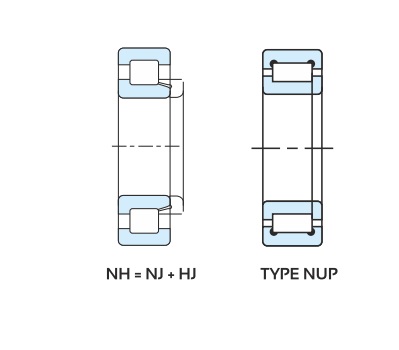

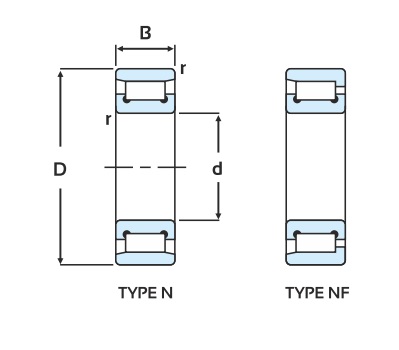

Cylindrical Roller Bearings

Cylindrical roller bearings are precision-engineered bearings designed to handle high radial loads while minimizing friction. Their cylindrical rollers allow for efficient load distribution, making them ideal for high-speed applications in various industrial machinery, including motors, pumps, and gearboxes

| Dimensions | |

|---|---|

| Bore Diameter | 700 mm |

| Outside Diameter | 930 mm |

| Width | 160 mm |

| Performance | |

|---|---|

| Fatigue Load Limit | 449 KN |

| Dynamic Load Rating | 34 19 KN |

| Static Load Rating | 6903 KN |

| Boundary Dimensions | ||

|---|---|---|

| d | 700 mm | Bore Diameter |

| D | 930 mm | Outside Diameter |

| B | 160 mm | Width (Outer Ring) |

| r | 8 mm | Chamfer on Inner Ring |

| Dynamic Load Rating | ||

|---|---|---|

| Cr(KN) | 34 19 | Dynamic |

| Cor(KN) | 6903 | Static |

| Cr(Kgf) | 348494 | Dynamic |

| Cor(Kgf) | 703619 | Static |

| Mass | ||

|---|---|---|

| mass (kg) | 300 |

| File | Actions |

|---|---|

| Cylindrical Roller Bearing |

Industrial

Bearing Solutions For The Ceramic Industry

Features & Benefits

- An extensive range of products suitable for demanding environments.

- Longevity of service life as it can withstand humidity, dust and high-speed application.

- Special products are made of advanced materials, special seals, and lubricants.

- Condition monitoring service to prevent any unplanned stoppage

- Low maintenance and maximized uptime makes it economical and reliable.

Bearing Applications

- Low speed due to various reasons

- Contamination that can lead to major downtime

- Vibration that is directly related to increased friction

- Heavy loads which need careful monitoring and maintenance.

- Optimized internal geometry for lowered friction and improved precision

- Seal design to prevent environmental contaminants

- Special heat treatment to prevent overheating and eliminating downtime to great extent

- High-load carrying capacity for proper flow

- High-operational reliability which means low on maintenance

Ceramic Bearing Styles and Sizes

Steel Cage Bearings:

- Surface hardened and lightweight cage design

- Suitable for high-speed applications

- Gives adequate performance for majority of applications

Brass Cage Bearings:

- Better performance in shock load applications

- Suitable for high centrifugal loading

- Better performance in reversing application

- Two-piece cage design: This allows both rows to run independently, avoiding the risk of roller slippage, smearing and cage damage.

- Enhanced roller finishing to reduce friction: Enhanced race/roller surface finish results in improved lubrication film, which avoids metal-to-metal contact and lowers bearing operating temperature.

- Improved and robust cage design: Helps in better roller cage interaction and can accommodate more rollers and longer cage life by providing surface treatment.

- Central Guide Ring/Flange: The central guide ring/flange provides optimal guidance to the rollers and limits rollers skew thus, avoids unnecessary force on the cage.

- Maximum and Larger Rollers: This enhances load carrying capacity.

- Size range: 30-2000 mm OD

- Variants: Straight bore, Tapered bore (1:12, 1:30)

- Cage: Brass, Steel

- Clearances: C2, CN, C3, C4, C5

HCR Wear Resistant Bearings

Features & Benefits

- Optimized coating with metal-containing amorphous carbon with a multilamellar structure

- No columnar structure provides high adhesion strength

- High dimensional accuracies

- Low coefficient of friction even in dry condition: Resistant to adhesive wear and micro pitting

- Enhanced fatigue life in insufficient lubrication condition

- Debris tolerance: removes dents created in the contaminated application

Oil Impregnated Bearings

Oil impregnated bearings composed of 70-80% of lubricating synthetic oil. Oil is moulded and solidified with polymer to form a casing which acts as a lubricant reservoir throughout the bearing’s life.

- Improved lubrication with consistent lubricant supply

- Superior lubricant: Synthetic oil

- Excellent performance in water and dusty environment

- Environment-friendly molding process

- Long life and maintenance-free

- Higher operational reliability

- No re-lubrication needed

- No lubricant washout issue

Sealed Spherical Roller Bearings

Sealed Spherical Roller bearings are like conventional spherical roller bearing in design and features, however for extra protection of bearing and lubricant from any external agents it has contact seals in the recesses of the outer ring.

- Effective and high-performance contact seals

- Different seal materials to suit different operating temperatures

- Reduced lubricant consumption

- Lower operating and maintenance costs

- Excellent protection against water splashes and contamination

Insulated Ball Bearings

Features

- Aluminium oxide coating using plasma spraying technology

- Current insulation

- High thermal stability

Benefits

- Extending bearing service life by avoiding damage caused by electric current flow.

- Higher operational reliability of electrical machinery

Download Cement Catalogue

Mostly Used Bearings

Our Offerings

NBC manufactures over 200 million bearings each year offered in 2300+ variants to serve the customers in Automotive, Railway, Aerospace and Industrial segments. Product range includes ball bearings, taper roller bearings, cylindrical bearings, spherical roller bearings, needle roller bearings, railway axle boxes and other special products.Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

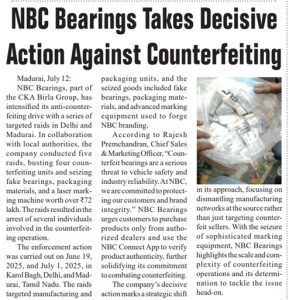

NBC Bearings Cracks Down on Counterfeiters with Major Raids in Delhi and Madurai

Seizes fake bearings and machinery worth over ?72 lakh in coordinated enforcement actionNational Engineering Industries Ltd. (NEI), part of the CKA Birla Group and manufacturer

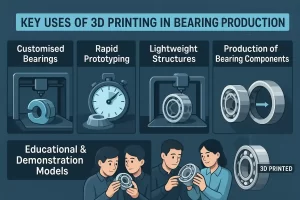

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

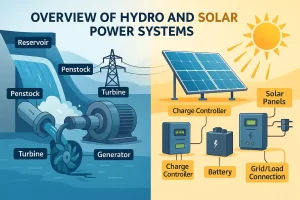

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

Request more information

Leadership quotes

Features:-

- Cylindrical Design: Cylindrical roller bearings feature a unique cylindrical shape that allows for even load distribution and efficient performance, reducing stress and extending the lifespan of machinery components.

- Robust Construction: These bearings are built to handle high radial loads, making them ideal for demanding industrial applications and ensuring reliability under heavy-duty conditions.

- High Radial Load Capacity: Cylindrical roller bearings are specifically designed to manage significant radial loads, making them perfect for applications that experience intense load variations.

- Low Friction: The precision design of these bearings minimizes friction, reducing heat generation and improving the overall efficiency and longevity of the machinery.

- Sealed Options: Cylindrical roller bearings are available with seals or shields, offering excellent protection against contaminants, which helps in extending the bearing’s service life.

- Versatility: These bearings are adaptable and can be customized to suit various industrial needs, offering flexibility across different applications.

- Enhanced Efficiency: The low-friction design and robust construction lead to improved performance and energy efficiency, contributing to lower operational costs.

Applications:

- Electric Motors

- Pumps and Compressors

- Gearboxes

- Wind Energy

- Steel Mills

- Machine Tools

- Automotive Transmissions

- And many more…

Why Choose Us:

- Unwavering Quality: We are committed to delivering the highest standards of quality and reliability in every bearing we produce, ensuring your machinery operates at peak performance.

- Deep Industry Expertise: With years of experience, we understand our customers’ unique needs and provide expert guidance to help you find the perfect solutions.

- Exceptional Customer Support: Our dedicated team offers comprehensive technical assistance, custom solutions tailored to your requirements, and prompt, attentive responses to all inquiries.

- Competitive Pricing: We offer flexible, cost-effective solutions without compromising on performance, ensuring you get the best value for your investment.

- Global Reach: Our extensive network ensures that our premium tapered roller bearings are readily accessible worldwide, providing you with the quality you need, wherever you are.

Choosing NBC Bearings means partnering with a brand known for reliability, quality, and exceptional support—making us your trusted choice for all bearing solutions.