Bearings are present everywhere. Every machine or instrument has the fundamental involvement of a bearing in it. Therefore, in the world of bearings, adherence to industry standards is paramount to ensure reliability, performance, and compatibility across various applications. ANSI (American National Standards Institute), ISO (International Organization for Standardization), and ASTM (American Society for Testing and Materials) are three prominent organizations that develop and maintain standards for bearings. In this comprehensive guide, we’ll explore the role of these standards in the bearing industry, delve into the specific standards set by each organization, and provide insights on how to choose the right standard for your application.

ANSI, ISO, and ASTM are internationally recognized organizations responsible for developing and publishing standards across various industries, including bearings. These standards serve as guidelines for manufacturers, engineers, and end-users, ensuring consistency, quality, and safety in product design, manufacturing, and performance.

Role of Standards in the Bearing Industry

Standards play a crucial role in the bearing industry by establishing uniform specifications, dimensions, and performance criteria for bearings and related components. By adhering to these standards, manufacturers can ensure interoperability, reliability, and compatibility of bearings across different systems and applications. Standards also facilitate communication and collaboration among industry stakeholders, enabling seamless integration and interchangeability of bearings in various mechanical systems.

ANSI Standards for Bearings

ANSI develops and maintains standards for various aspects of bearing design, performance, and testing. These standards cover dimensions, tolerances, materials, lubrication, and testing procedures for different types of bearings, including ball bearings, roller bearings, and thrust bearings. ANSI/ABMA (American Bearing Manufacturers Association) standards are widely used in North America and serve as a benchmark for bearing manufacturers and users worldwide.

ISO Standards for Bearings

ISO is a global organization that develops and publishes international standards for bearings under the ISO 15 series. ISO standards define bearing dimensions, tolerances, clearances, and technical specifications for rolling bearings used in industrial and automotive applications. ISO standards ensure global consistency and compatibility of bearings, enabling seamless interchangeability and integration across different regions and industries.

ASTM Standards for Bearings

ASTM develops and maintains standards for bearing materials, testing methods, and performance evaluation. ASTM standards cover a wide range of topics, including bearing steels, lubricants, corrosion resistance, and fatigue testing. These standards provide guidelines for manufacturers, researchers, and end-users to ensure the quality, reliability, and safety of bearings in various applications and environments.

How to Choose the Right Standard?

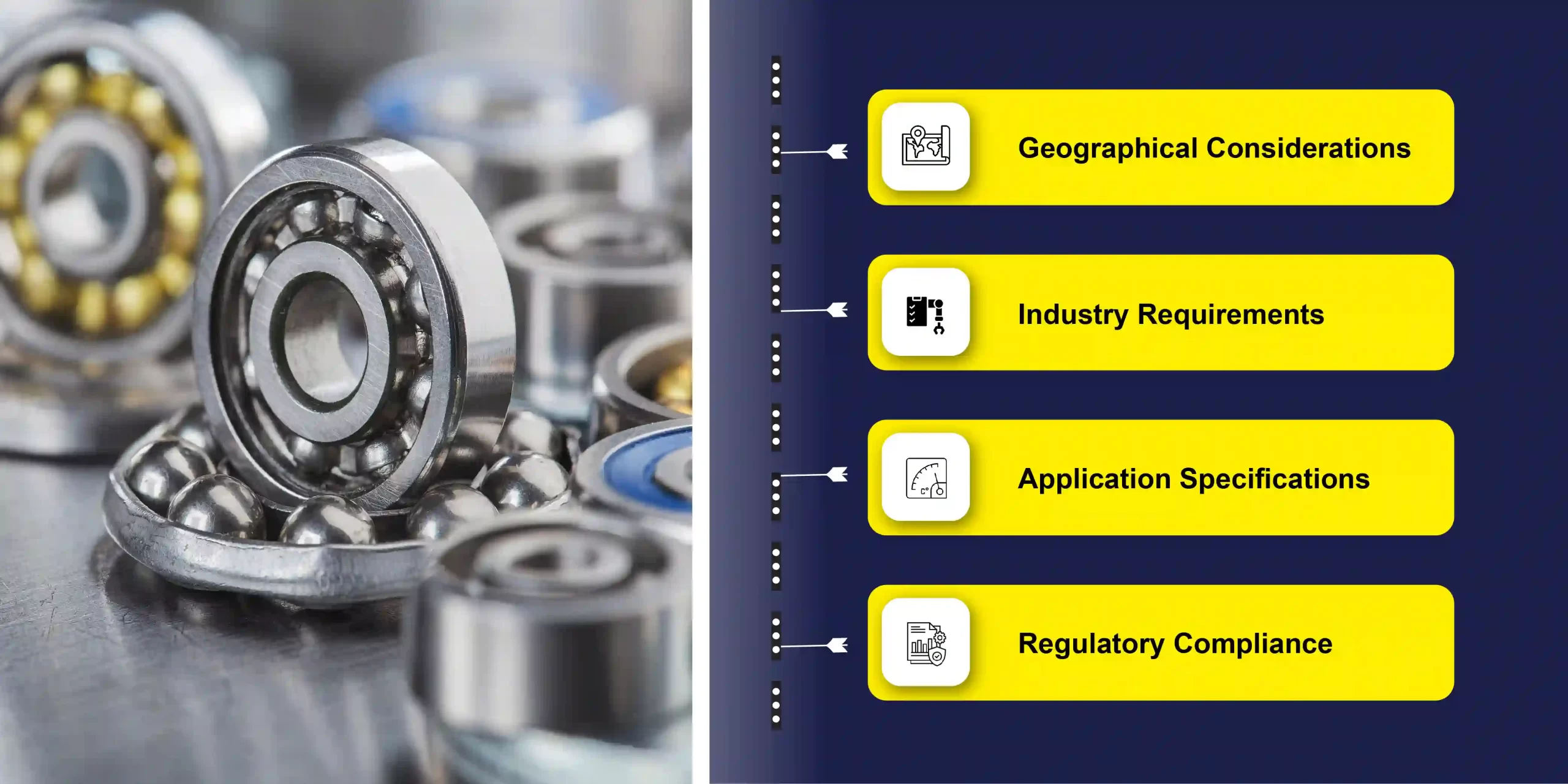

Choosing the right standard for bearings depends on several factors, including geographical location, industry requirements, application specifications, and regulatory compliance. Consider the following factors when selecting a standard:

- Geographical Considerations: ANSI standards are commonly used in North America, while ISO standards are prevalent globally. Choose a standard that aligns with your geographical location and market requirements.

- Industry Requirements: Some industries, such as aerospace, automotive, and medical devices, may have specific standards or regulations governing bearing performance and quality. Ensure compliance with industry-specific requirements when selecting a standard.

- Application Specifications: Consider the operating conditions, load requirements, speed, temperature, and environmental factors of your application. Choose a standard that best meets the performance and durability requirements of your specific application.

- Regulatory Compliance: Ensure that the selected standard complies with relevant regulatory requirements, such as safety standards, environmental regulations, and industry certifications.

FAQ's

What is a bearing standard?

A bearing standard is a set of guidelines, specifications, and technical requirements established by organizations such as ANSI, ISO, and ASTM to ensure consistency, quality, and performance in the design, manufacturing, and use of bearings.

What is the ISO standard for bearing tolerances?

The ISO standard for bearing tolerances is defined in ISO 492:2014, which specifies the dimensional and running accuracy tolerances for rolling bearings, including radial bearings and thrust bearings.

What is the ISO standard bearing designation?

The ISO standard bearing designation follows a standardized format, consisting of a series of numbers and letters that represent the bearing type, series, bore diameter, and special features. For example, a bearing designation “6204” indicates a deep groove ball bearing with a bore diameter of 20 mm.

What is the ISO standard for bearing temperature?

The ISO standard for bearing temperature is not explicitly defined, as bearing temperature depends on various factors such as operating conditions, lubrication, speed, and load. However, ISO 15312:2003 provides guidelines for measuring and monitoring bearing temperature during operation.

Why do we use ASTM standards?

ASTM standards are used to ensure the quality, reliability, and safety of bearings by establishing standardized testing methods, material specifications, and performance criteria. Manufacturers, researchers, and end-users rely on ASTM standards to evaluate bearing materials, design parameters, and performance characteristics in diverse applications and environments.