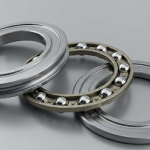

Thrust roller bearings play a crucial role in a wide range of machines by reducing friction and supporting axial loads. Their design ensures smooth movement, protects components from wear, and contributes to longer equipment life. For engineers, maintenance teams, and equipment designers, understanding how these bearings work—and where each type is best suited—can significantly improve machine performance and reliability.

What Are Thrust Roller Bearings?

Thrust roller bearings are specialized bearings designed to handle axial loads, meaning forces acting parallel to the shaft. They prevent unwanted axial movement and help maintain alignment inside rotating equipment.

These bearings are available in multiple designs, each engineered to meet different load, speed, and application requirements.

Key characteristics include:

-

Ability to support axial loads

-

Reduced friction between moving surfaces

-

Wide variety of design types for different applications

Because they operate in demanding environments—from high-speed machinery to heavy industrial systems—thrust roller bearings must be selected carefully to ensure reliability.

How Thrust Roller Bearings Work

The primary function of a thrust roller bearing is to support loads acting along the axis and ensure smooth rotational movement. This is achieved by minimizing friction between the bearing surfaces, which helps protect components from premature wear.

How they enhance performance:

-

Support axial loads efficiently

-

Reduce frictional losses

-

Improve operational reliability and service life

Choosing the right thrust bearing helps machines operate smoothly under load, reduces breakdowns, and lowers maintenance costs.

Main Types of Thrust Roller Bearings

Thrust bearings come in several designs, each suited for specific working conditions.

1. Thrust Roller Bearings

Suitable for low-speed and light-load applications, thrust roller bearings distribute the load evenly. They are commonly used in mechanisms where minimal axial load is present.

Key advantages:

-

Best for low-speed setups

-

Handles smaller axial loads

-

Smooth, low-friction operation

2. Thrust Roller Bearings (Cylindrical / Roller Type)

Designed for higher loads and speeds, roller thrust bearings use cylindrical rollers to increase contact area and load capacity. These are preferred in heavy-duty machines that experience significant axial forces.

Advantages:

-

Handles higher loads

-

Suitable for moderate to high-speed operations

-

Enhanced durability due to larger contact area

3. Fluid Thrust Bearings

Fluid thrust bearings use a thin film of oil or gas to create a lubricating layer between surfaces. They are common in high-speed, precision applications like turbines and compressors.

Key benefits:

-

Ultra-low friction

-

Excellent for very high speeds

-

Smooth, stable operation

Where Thrust Roller Bearings Are Used

Thrust roller bearings are essential in industries where axial loads are common, such as:

-

Automobiles: automatic transmission systems, steering assemblies

-

Aerospace: helicopter rotors, aircraft turbine shafts

-

Marine: propeller shafts

-

Industrial Machinery: compressors, turbines, pumps, gear drives

Their reliability helps protect equipment, reduce downtime, and improve overall efficiency in these critical applications.

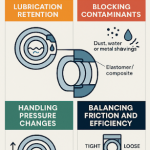

Materials and Lubrication

The performance of a thrust roller bearing depends heavily on its material and lubrication.

Common materials include:

-

High-grade steel

-

Adoption of Different material for improved durability

-

Advanced composites

Lubrication—whether oil or grease—is equally important. Proper lubrication prevents metal-to-metal contact, reduces friction, and controls operating temperature. Regular inspection and replenishment significantly extend bearing life.

Selecting the Right Thrust Roller Bearing

Choosing the correct bearing requires understanding the application’s operating conditions.

Considerations include:

-

Axial load capacity

-

Operating speed

-

Environmental conditions

-

Lubrication method

-

Material suitability

The right bearing ensures smoother operation, reduces unexpected failures, and keeps maintenance costs under control.

Maintenance and Troubleshooting

Regular inspection and care help maintain bearing performance.

Maintenance tips:

-

Check for wear, discoloration, or scoring

-

Ensure proper lubrication

-

Watch for unusual noise or vibration

-

Maintain clean operating conditions

Proactive maintenance prevents small issues from becoming major failures.

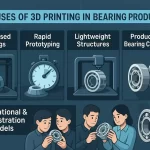

Future Trends in Thrust roller Bearing Technology

Bearing technology continues to evolve. Key developments include:

-

Advanced materials for longer life and lower friction

-

Optimized designs for greater load efficiency

-

Smart bearings with condition-monitoring sensors

These innovations aim to reduce downtime and enhance reliability across industries.

Why Choose NBC Bearings?

NBC Bearings is one of India’s most trusted bearing manufacturers, known for:

-

Decades of design and engineering expertise

-

World-class manufacturing capabilities

-

Strict quality control at every stage

-

Customized bearing solutions for diverse industries

-

Reliable, long-life performance in demanding applications

NBC’s thrust roller bearings are engineered to deliver consistent axial load support, low friction, and dependable operation in even the toughest environments.