We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation. While this is true, bearings are far more important, and the application of these crucial components is just not limited to machines. In reality, bearings are essential to nearly every moving system, from heavy industrial machines to precision surgical robots. Their role goes beyond just reducing friction; they support motion, precision, reliability, and efficiency, making them a vital part of traditional and emerging technologies. Talking about emerging technologies, bearings are now widely being used in medical devices, renewable energy, robotics & automation, and more. One such emerging area where bearings are playing a role is drones and UAVs.

The Rise of UAVs and Drones

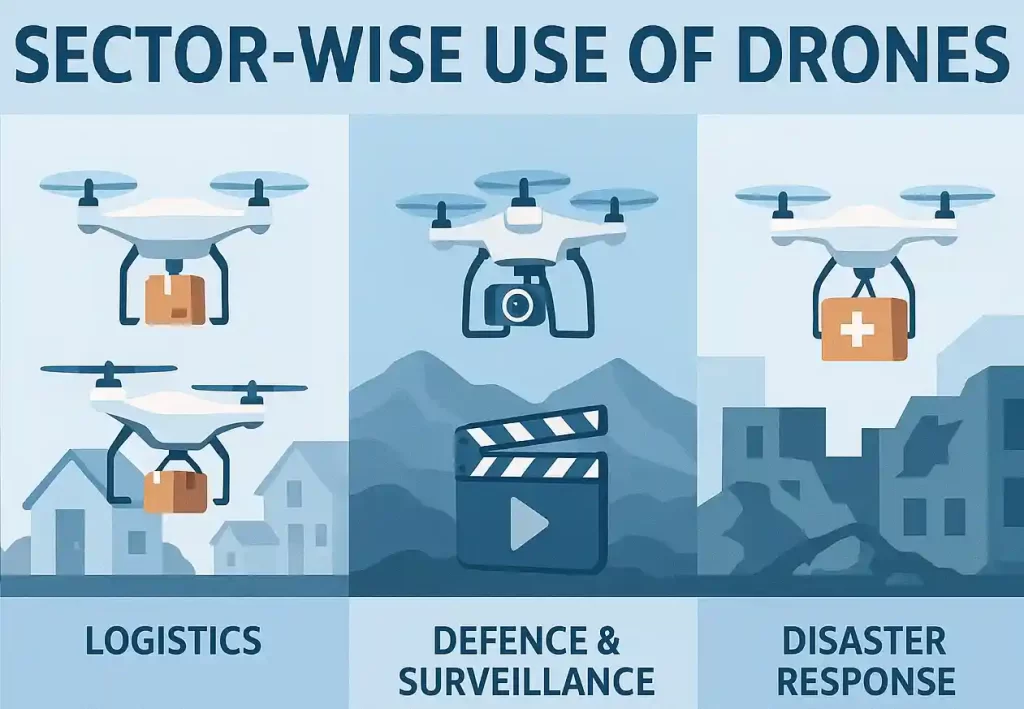

Drones and UAVs are being used extensively, from being used in the military to being used in industries like logistics, agriculture, surveillance, filmmaking, disaster management, and more. According to a report by Statista, the revenue in the drone market worldwide amounts to US$4.4bn in 2025. Now, these drones and UAVs, in order to function efficiently, require high-precision bearings that can withstand high rotational speed, rapid directional change, vibrations, and harsh conditions, increasing the demand for precision bearings.

|

Sector |

Use of Drones |

|

Agriculture |

Utilised in crop monitoring, spraying & soil analysis. |

|

Logistics |

Aids with parcel drops & last-mile deliveries. |

|

Defence & Surveillance |

Utilised in tactical operations, patrolling, etc. |

|

Media & Filmmaking |

Needed for cinematography, aerial photography, etc. |

|

Disaster Response |

Aids supply drops, aerial assessment, etc. |

Role of Bearings in Drones & UAVs

Bearing has an important part to play in drones & UAV systems for proper and smooth working. Drone motors and control systems are generally equipped with bearings. Bearings have an important part to play in this system, including:

- Smooth Motor Movement: The main function of a bearing is to enable effective power delivery. Drones & UAVs are typically equipped with brushless motors, and bearings are an integral part of these motors. Bearings assist the rotor to rotate smoothly, reducing vibration, and wobble.

- Precision Movement: Drones and UAVs are fitted with control systems that manage the movements of these appliances. Bearings are an essential part of the control system, ensuring precise and responsive movement, allowing the drone to manoeuvre accurately.

- Minimise Vibration & Noise: Precision-made bearings reduce vibration & friction-related noise resulting in quiet operation and help maintain the accuracy of its flight.

- Durability: Drones operate at extreme high-speed and at harsh conditions. Bearings fitted in drones and UAVs are built to handle extreme rotation and dampen vibration, enhancing motor’s efficiency and reducing the chances of failure.

Types of Bearings Used in Drones and UAVs

- Ball Bearing: Ball bearing is most commonly utilised in drone’s & UAVs motors, propellers, and gimbals. Ball bearing plays an important part in supporting the axial and radial load facilitating smooth rotation of moving components. Motor in drones and UAVs spin at extremely high speed producing friction and heat, ball bearing minimises friction and heat and promotes smooth & efficient operation.

- Roller Bearing: Roller bearings, such as tapered roller bearings and cylindrical roller bearings, are mostly utilised in drones, particularly drones designed for maximum heavy radial load capacity. Drones used in cargo delivery, spraying for agriculture, or military operations incorporate roller bearings owing to their maximum load capacity.

- Ceramic Bearing: Ceramic bearings are preferred type for drones with high-performance motors, racing drones, and drones operating in harsh conditions. Ceramic bearings offer good resistance to heat, corrosion, and wear.

- Thrust Bearing: Thrust bearings are used in drone & UAVs systems to support axial loads. Thrust bearing manages stability and premature wear of components.

- Angular Contact Bearing: Angular contact bearing is used to handle both radial and axial loads. These bearings are designed to provide better load handling & stability. Angular contact bearings are used in high-speed and heavy lift drones.

Drone Components Where Bearings Are Used

Bearings are vital parts of drone systems and are employed in numerous parts, such as:

- Drone Motors: Motors in drones are equipped with bearings, commonly ball bearings. Bearings in motors bear the drone rotor, reduce friction, and facilitate smooth rotation of components.

- Rotors & Propellers: Bearings are installed in propeller assemblies to facilitate even and stable rotation of the propeller.

- Camera Gimbals: Bearings are installed in camera gimbals, mainly miniature or precision bearings, allowing smooth movement of the camera.

- Payload Mechanism: Drones designed to carry heavy loads are fitted with bearings to help in the controlled release or transport of goods.

- Landing Gear: Bearings in landing gears are used to cater for loads during takeoff and landing.

Industry Applications of Bearings in Drones

- Agriculture: Drones are now being used widely in the agriculture field, specifically for spraying, crop monitoring, field mapping, soil analysis, and more. Bearings are used in motor systems of these drones and built to resist dust and moisture.

- Surveillance & Defence: Drones and UAVs are emerging as a key component of defence, serving a vital function in intelligence gathering, surveillance, reconnaissance, precision strikes and so forth. Bearings employed in these drones & UAVs are extremely robust and are made to function in harsh conditions.

- Filmmaking & Media: Drones deployed in media & filmmaking are fitted with precision bearings to provide smooth, shake-free camera movement. Bearings employed here are designed to dampen operation noise.

- Logistics & Delivery: Drone are now an integral part of the logistics and delivery industry. Bearings in these drones are designed to endure safe flight operation for accurate parcel drops.

- Infrastructure: Drones used in detailed visual inspection of infractures are fitted with bearings responsible for stable flight around structures like bridges and towers.

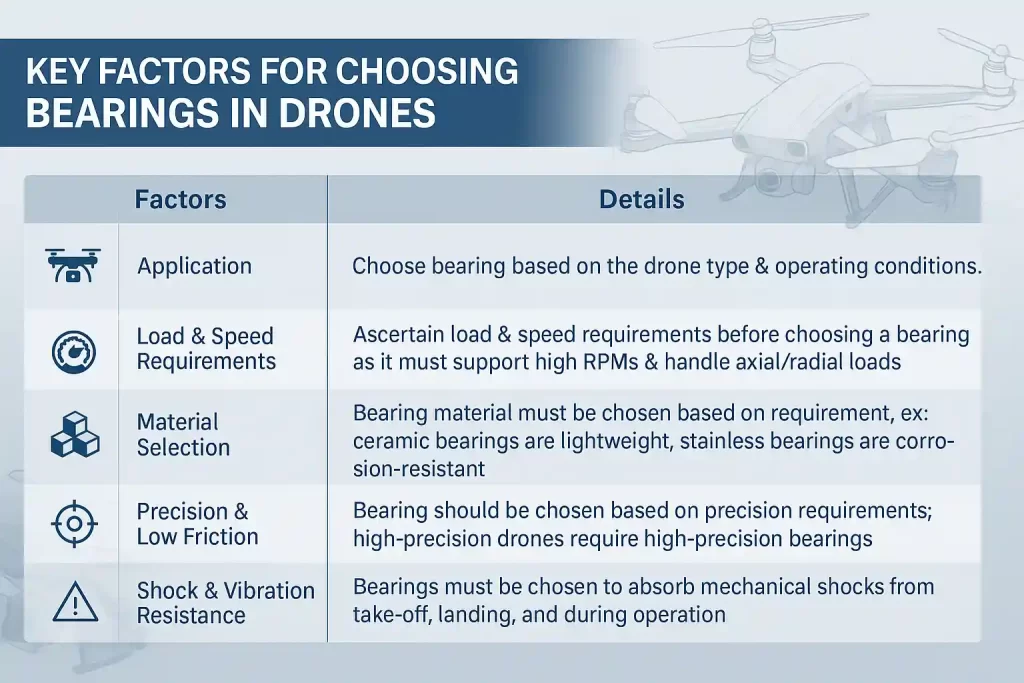

Selection of the Right Bearings for Drone Application

- Application: Choose bearing based on the drone type & operating conditions.

- Load & Speed Requirements: Ascertained load & speed requirements before choosing a bearing as it must support high RPMs & handle axial or radial loads.

- Material Selection: Bearing material must be chosen based on requirement, ex: ceramic bearings are lightweight, stainless bearings are corrosion resistant.

- Precision & Low Friction: Bearing should be chosen based on precision requirements, high precision drones require high-precision bearings.

- Shock & Vibration Resistance: Bearings must be chosen to absorb mechanical shocks from take-off, landing, and during operation.