Introduction

In the real world, machines don’t always run under perfect conditions. Shafts bend under load, mounts shift slightly during installation, and components expand when exposed to heat. These small misalignments might seem harmless, but they can quickly lead to vibration, excess heat, and early bearing failure. Self-aligning ball bearings are designed to handle exactly these challenges. Their unique geometry allows them to adjust naturally to misalignment — keeping machinery running smoothly, quietly, and efficiently. At NBC Bearings, we combine this intelligent design with precision manufacturing and high-quality materials to deliver self-aligning ball bearings that perform reliably across a wide range of industrial applications.What Are Self-Aligning Ball Bearings?

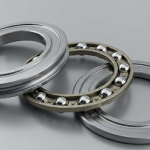

Unlike standard deep-groove ball bearings, self-aligning ball bearings have two rows of balls that run on a spherical outer raceway. This allows the inner ring to tilt slightly relative to the outer ring, compensating for shaft misalignment — both static (from installation) and dynamic (from operation). Because the loads are distributed evenly across both rows of balls, friction and wear are minimized. These bearings can typically tolerate up to three degrees of misalignment, making them ideal wherever perfect shaft alignment is difficult — such as in long shafts or systems subject to deflection or thermal expansion.How Do They Work?

The secret lies in their spherical outer raceway. When the shaft or housing becomes misaligned, the two rows of balls simply pivot within the spherical race, keeping contact uniform and stress low. This clever design:- Corrects both static and dynamic misalignment, preventing edge loading.

- Maintains low friction, even at high operating speeds.

- Handles primarily radial loads, with capacity for light axial (thrust) loads.

- Uses strong yet lightweight steel or polyamide cages to evenly space the balls and minimize noise.

Key Features of NBC’s Self-Aligning Ball Bearings

NBC’s self-aligning ball bearings are designed to perform consistently across challenging applications. Some standout features include:- Up to three degrees of alignment correction — perfect for systems with unavoidable shaft deflection.

- Low friction and heat generation, ensuring cooler, longer-lasting performance.

- Optimized for radial loads while capable of handling light axial forces.

- Available in open and sealed variants for both clean and contaminated environments.

- Maintenance-friendly design, with pre-lubricated sealed options.

- Wide size range and tolerance options, suitable for industries such as textiles, mining, food processing, and general engineering.

Why Choose Self-Aligning Ball Bearings?

1. Longer Service Life

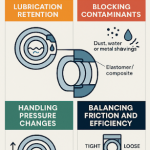

Because they automatically correct misalignment, these bearings run cooler and distribute loads evenly — dramatically reducing wear and extending lifespan. NBC’s high-precision manufacturing ensures excellent geometry and surface finish for even greater durability.2. Lower Maintenance Costs

With less wear and fewer alignment issues, there’s less need for frequent servicing. Sealed versions further reduce maintenance by keeping contaminants out and lubrication in, cutting downtime and overall cost of ownership.3. Better Efficiency

These bearings maintain stability at high speeds, even when shafts flex or expand. Their low friction design minimizes energy loss and supports smoother machine operation, making them a great choice for energy-efficient systems.4. Quiet, Reliable Operation

Minimal friction and uniform motion translate into low noise and vibration levels — ideal for fans, HVAC units, and other applications where smooth, quiet operation matters.5. Enhanced Protection

NBC’s sealed self-aligning bearings offer excellent protection from dust, moisture, and other contaminants. This preserves lubricant quality and extends the life of both bearing and equipment.Common Applications

Self-aligning ball bearings are found across a wide variety of industries:- Automotive: Alternators, transmissions, and components with flexible shaft couplings.

- Industrial Machinery: Conveyors, pumps, compressors, and fans.

- Mining & Construction: Belt drives, crushers, and vibrating screens exposed to heavy loads and misalignment.

- Textile & Paper: High-speed spindles and winding equipment.

- Renewable Energy: Wind turbines, where deflection and heavy loading are common.

Selecting the Right Bearing

Choosing the right self-aligning bearing means considering several factors:- Load type and direction: Primarily radial with light axial support.

- Speed: Higher speeds call for precision tolerances and strong cage materials.

- Expected misalignment: Estimate static and dynamic angles.

- Environment: In dusty or wet conditions, sealed versions are recommended.

- Bearing size and fit: Avoid undersizing (which causes overheating) or oversizing (which increases cost).

Installation and Maintenance Tips

To get the best performance from your self-aligning bearings:- Use precision tools during installation — avoid impact or force fitting.

- Maintain proper shaft and housing tolerances.

- Monitor noise and vibration levels regularly for early warning of issues.

- Follow NBC’s lubrication recommendations for your operating conditions.

- Keep seals clean and intact to prevent contamination.

- Replace bearings showing signs of excessive heat, vibration, or wear.