- Home

- /

- Roller Bearings

- /

- Spherical Roller Bearings

- /

- ID-22322 CC W33

22322 CC W33

Spherical Roller Bearing

Spherical Roller Bearings are designed to excel in a wide array of applications which demand performance and versatility. The spherical design allows these bearings to handle radial and axial loads easily across a wide range of industries.

Overview

Technical Specification

Download PDF

Overview

| Dimensions | |

|---|---|

| Bore Diameter | 110 mm |

| Outside Diameter | 240 mm |

| Width | 80 mm |

| Performance | ||

|---|---|---|

| Fatigue Load Limit | 96.4 KN | |

| Dynamic Load Rating | 744 KN | |

| Static Load Rating | 935 KN |

Technical Specification

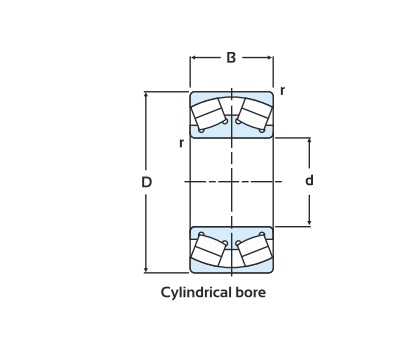

| Boundary Dimensions | ||

|---|---|---|

| d | 110 mm | Bore Diameter |

| D | 240 mm | Outside Diameter |

| B | 80 mm | Width (Outer Ring) |

| r | 3 mm | Chamfer on Inner Ring |

| Dynamic Load Rating | ||

|---|---|---|

| Cr (KN) | 744 | Dynamic |

| Cor (KN) | 935 | Static |

| Cr (Kgf) | 75866 | Dynamic |

| Cor (Kgf) | 95342 | Static |

| Calculations | ||

|---|---|---|

| e | 0.35 | Limiting Value |

| Y1 | 1.9 | Calculation Factor |

| Y2 | 2.9 | Calculation Factor |

| Y0 | 1.9 | Calculation Factor |

| Mass | ||

|---|---|---|

| mass | 17.9 |

Download PDF

| File | Actions |

|---|---|

| Spherical Roller Bearings |

Features:-

- Spherical Design: The distinct spherical shape enables these bearings to remove problems of misalignment, by reducing operational stress and wear on the machinery components.

- Sturdy Built: Spherical roller bearings can withstand heavy loads and harsh operating conditions.

- High Load Capacity: These variants can handle both radial and axial loads, which is why these bearings are ideal for applications which operate under variable loads.

- Reduced Friction: The design helps minimize friction, leading to lower temperature peaks and enhanced efficiency.

- Sealed Variants: Spherical roller bearings may also come with seals or shields, which provide strong resistance to contaminants and extend their service life.

- Versatility: Spherical roller bearings are flexible and adapt easily to customer needs across a wide range of industries.

- Efficiency Improvement: Reduced friction and adaptable design leads to improved equipment and energy efficiency.

Applications:

- Mining and Quarrying

- Paper & Pulp Industry

- Heavy Machinery

- Wind Energy

- Marine & Offshore

- Steel & Metal Processing

- and many more…

Why Choose Us:

- Uncompromising quality while ensuring consistent quality and reliability.

- Extensive experience of understanding customers’ needs and providing expert guidance.

- Customer support offering technical assistance, custom solutions, and prompt responses to inquiries.

- Competitive Pricing for flexible cost-effective solutions that deliver superior performance.

- Wide network ensuring high-quality tapered roller bearings are accessible across the world.

Market Segments

Bearing Categories

Tapered Roller Bearings | Single Row Tapered Roller Bearings | Double Row Tapered Roller Bearings | Four Row Tapered Roller Bearings | Cylindrical Roller Bearings | Single Row Cylindrical Roller Bearings | Double Row Cylindrical Roller Bearings | Four Row Cylindrical Roller Bearings | Cylindrical Thrust Roller Bearings | Full Complement Cylindrical Roller Bearings | Spherical Roller Bearings