Introduction

Industrial growth across the world is built on one fundamental capability—the ability to manufacture reliable, precise, and high-performance components. From automotive systems and heavy machinery to rail transport and aerospace applications, every sector depends on components that can perform consistently under demanding conditions.

This is where manufacturing excellence becomes a decisive factor.

From NBC’s perspective, manufacturing excellence is not just a competitive advantage. It is the foundation that enables industries to operate efficiently, scale with confidence, and innovate without compromise.

What Is Manufacturing Excellence?

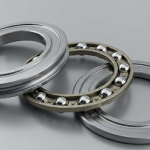

Manufacturing excellence is the discipline of delivering consistent quality through strong engineering, robust processes, and a zero-defect mindset. For a bearings manufacturer like NBC, precision is measured at the micron level, where even the smallest deviation can influence friction, load capacity, noise levels, and service life.

Key elements of manufacturing excellence include:

Robust quality management systems

Highly skilled engineering and operations teams

Advanced automation and precision machinery

Standardised processes with continuous improvement

Strong supplier integration and material quality control

Together, these elements create a manufacturing ecosystem where reliability is built into every product.

Why Manufacturing Excellence Fuels Global Industrial Growth

Modern industries rely heavily on precision-engineered components. Manufacturing excellence plays a critical role in global industrial growth in several ways:

1. Strengthens supply chain reliability

Industries can scale only when components are delivered on time and meet exact specifications. Precision manufacturing reduces rework, downtime, and operational disruptions.

2. Improves equipment performance and lifespan

High-quality components enhance durability and efficiency, reducing maintenance costs for OEMs and end users alike.

3. Enables innovation

Emerging technologies such as electric mobility, renewable energy, automation, and advanced robotics demand tighter tolerances and specialised designs. Manufacturing excellence makes this innovation possible.

4. Enhances global competitiveness

Nations and companies that invest in advanced manufacturing strengthen exports, attract global customers, and become integral parts of international supply chains.

NBC’s Perspective on Manufacturing Excellence

NBC Bearings is one of India’s most respected engineering and bearings manufacturers, driven by a deeply embedded culture of manufacturing excellence.

A strong Total Quality Management (TQM) culture

NBC follows a rigorous TQM philosophy focused on continuous improvement, process discipline, and defect prevention. This commitment has earned the company prestigious recognitions such as the Deming Prize and the Deming Grand Prize.

Advanced manufacturing infrastructure

NBC operates state-of-the-art manufacturing facilities equipped with CNC machining lines, automated assembly systems, precision heat treatment processes, and world-class metrology laboratories.

Engineering and R&D leadership

With more than 3,000 bearing variants across ball bearings, roller bearings, railway bearings, and next-generation solutions, NBC’s strength lies in its in-house R&D, material science expertise, and application-driven design capabilities.

Focus on sustainability and efficiency

Energy-efficient operations, waste reduction initiatives, and environmentally responsible practices enable NBC to align with global sustainability standards.

A growing global presence

Serving customers across 30+ countries, NBC supports industries worldwide with consistent quality, dependable supply, and technical confidence.

Why Manufacturing Excellence Matters for a Bearings Manufacturer

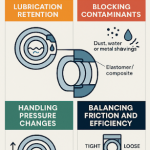

Bearings are critical machine components that directly impact speed, efficiency, safety, and reliability. They support rotating equipment across industries and must perform flawlessly under varying loads and speeds.

Manufacturing excellence ensures:

Accurate dimensions for perfect assembly fit

Reduced friction and heat generation

Longer bearing life

Controlled noise and vibration

Reliable performance under extreme operating conditions

Such consistency is possible only through disciplined engineering, precise process control, and continuous monitoring.

How Manufacturing Excellence Supports Global Economies

Countries aiming for long-term industrial development depend on strong manufacturing ecosystems. Reliable manufacturing enables nations to:

Accelerate industrial expansion

Reduce import dependency

Strengthen export capabilities

Create skilled employment opportunities

Attract foreign investment

Support innovation in emerging sectors

A bearings manufacturer that operates at global standards contributes directly to these national growth objectives.

Real-World Applications of Manufacturing Excellence

Electric mobility

EV motors and drivetrains require high-precision bearings to operate at higher speeds with minimal friction losses.

Railway modernisation

Traction motors and axle box bearings must withstand shock loads, high temperatures, and long service cycles.

Renewable energy

Wind turbines rely on large, durable bearings capable of handling fluctuating loads in harsh outdoor environments.

Smart factories and automation

Robotics and automated systems demand bearings that ensure smooth, reliable movement over extended duty cycles.

NBC’s Commitment to Future Industrial Growth

NBC continues to invest in advanced manufacturing technologies, digital transformation, Industry 4.0 practices, predictive quality systems, and R&D for next-generation bearing solutions.

The company believes that manufacturing excellence is not a destination, but a continuous journey—one that strengthens industries, empowers employees, and contributes to a more efficient and sustainable world.

Conclusion

Manufacturing excellence remains the backbone of global industrial progress. It enables industries to grow faster, innovate with confidence, and operate reliably. From NBC’s perspective, excellence is both a responsibility and a commitment to the future of engineering.

With an unwavering focus on quality, precision, and innovation, NBC continues to play a vital role in supporting global industrial success.

Frequently Asked Questions

1. Why is manufacturing excellence important for a bearings manufacturer?

It ensures precision, reliability, and long service life—critical for industrial, automotive, and railway applications.

2. How does manufacturing excellence support industrial growth?

It improves efficiency, reduces downtime, strengthens supply chains, and enables advanced technologies.

3. What makes NBC a trusted bearings manufacturer?

A strong TQM culture, advanced manufacturing infrastructure, and proven engineering expertise.

4. How does manufacturing excellence support the EV industry?

High-precision bearings enable higher speeds, lower friction, and improved motor efficiency.

5. What role does quality control play in manufacturing excellence?

Quality control ensures consistency, prevents defects, and guarantees safe and reliable machine operation.