Introduction

Large Diameter Bearings play a vital role in industries that operate with heavy loads, extreme forces, and demanding cycles. Sectors such as mining, steel, cement, wind energy, construction equipment, marine systems, and power plants rely heavily on these bearings. Their failure can lead to severe downtime, high repair costs, and safety risks.

This makes failure prevention a critical objective for every plant and every equipment manufacturer. NBC approaches this challenge with deep engineering expertise, advanced manufacturing, and a strong focus on reliability.

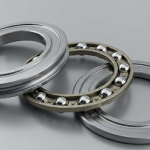

Understanding Large Diameter Bearings

Large Diameter Bearings are designed to support massive radial and axial loads while ensuring smooth rotational movement of heavy equipment. They are used in applications such as kilns, wind turbine hubs, offshore equipment, crushers, and large gearboxes. These bearings must handle:

Constant heavy load

Slow rotation or varied speed

Shock loads

Temperature fluctuations

Misalignment

Exposure to contamination

Their size and operating conditions make them more sensitive to installation errors, lubrication issues, and design limitations. This is why engineering precision and preventive care are essential.

Why Failure Prevention is Critical

Failures in Large Diameter Bearings are not ordinary maintenance issues. They can lead to:

Extremely high downtime costs

Risk to operator and equipment safety

Costly damage to housings, shafts, and rotating assemblies

Sudden production stoppage

Increased energy consumption due to friction

Reduced lifespan of machinery

A structured approach to failure prevention ensures reliable performance, improved productivity, and lower lifecycle cost.

Common Causes of Failure in Large Diameter Bearings

1. Inadequate lubrication

Lubrication is the most common cause of bearing failure. Wrong grease, insufficient lubrication intervals, or contamination in the lubricant all lead to wear and overheating.

2. Contamination

Dust, moisture, metal particles, and process impurities can penetrate the bearing, damaging rolling elements and raceways.

3. Misalignment

Improper alignment during installation or due to machine deformation increases internal stress and leads to premature failure.

4. Overloading

Unexpected load spikes or uneven load distribution cause fatigue and cracking in large bearings.

5. Improper mounting

Incorrect tools, impact loading during assembly, or mishandling can create invisible micro damage.

6. Thermal effects

High temperatures cause expansion, reduce lubricant viscosity, and accelerate fatigue.

7. Poor sealing

Weak sealing allows contaminants to enter and lubricant to escape.

NBC addresses each of these factors through precise engineering, manufacturing, and customer guidance.

NBC’s Engineering Approach to Failure Prevention

NBC Bearings uses a combination of advanced technology and engineering discipline to improve the reliability and life of Large Diameter Bearings.

Precision heat treatment

NBC applies special heat treatment cycles that improve hardness, reduce internal stress, and increase fatigue strength.

High accuracy machining

Large Diameter Bearings require perfect geometry. NBC uses advanced machining and grinding systems to ensure uniform load distribution and smooth operation.

Superior surface finishing

Optimised surface roughness reduces friction and prevents early wear.

Material selection and metallurgy

NBC uses premium grade alloy steels that deliver high strength, durability, and resistance to heavy stress.

Advanced cage design

Engineered cages improve stability at high loads and reduce friction between rolling elements.

Strict quality control

Every bearing goes through advanced metrology checks and TQM based validation to ensure zero compromise in reliability.

Custom engineered solutions

NBC supports OEMs with customised Large Diameter Bearings designed for specific load profiles and environmental conditions.

Condition Monitoring and Predictive Maintenance

NBC promotes predictive maintenance as a proven method to prevent failures. Techniques include:

Vibration signature analysis

Temperature and noise tracking

Inspection of wear patterns

Lubricant health monitoring

Early detection of misalignment or imbalance

These practices help customers identify early warning signs and act before failure occurs.

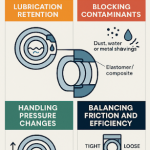

Lubrication and Sealing Excellence

Proper lubrication extends bearing life significantly. NBC guides customers on:

Choosing the right grease or oil

Setting lubrication intervals

Implementing automated lubrication systems

Using sealing systems that block dust, water, and contaminants

Good lubrication improves load carrying capability, reduces friction, and prevents metal to metal contact.

Installation and Handling Best Practices

Failures often begin during installation. NBC recommends:

Using the correct mounting tools

Ensuring clean workspace conditions

Maintaining proper alignment and preload

Avoiding impact or hammering

Following storage guidelines for large bearings

These practices eliminate errors that can shorten bearing life.

NBC’s Manufacturing Strength in Large Diameter Bearings

NBC has strong industrial capability to produce Large Diameter Bearings with high precision. Key strengths include:

Advanced manufacturing plants

Specialised lines for large sizes

Custom bearing design for industry specific applications

In house testing and validation

Strong application engineering team

Global supply capability for heavy industries

This enables NBC to support complex industrial projects with dependable bearing performance.

Industries That Depend on Reliable Large Diameter Bearings

Wind turbine systems

Marine and offshore equipment

Cement kilns and rotary equipment

Steel and metal processing plants

Mining and crushing machinery

Paper mills

Heavy industrial gearboxes

Defence and aerospace support systems

Each of these sectors demands long bearing life and zero unplanned downtime.

Conclusion

Failure prevention is essential for ensuring the reliability and longevity of Large Diameter Bearings. With strong engineering capability, advanced manufacturing, precision tools, and a deep focus on quality, NBC provides industries with bearings that deliver lasting performance. As a leader in Large Diameter Bearings, NBC continues to support global industries with solutions built for strength, accuracy, and long service life.

Frequently Asked Questions

1. What are Large Diameter Bearings used for?

They are used in heavy industrial applications such as wind turbines, cement plants, steel mills, and mining equipment.

2. What causes failure in Large Diameter Bearings?

Lubrication issues, contamination, misalignment, overload, and poor installation are common causes.

3. How does NBC improve the reliability of Large Diameter Bearings?

NBC uses precision machining, advanced heat treatment, strict quality control, and predictive maintenance support.

4. Why is lubrication important for Large Diameter Bearings?

Correct lubrication reduces friction, prevents wear, and protects the bearing from contaminants.

5. How can industries increase the life of Large Diameter Bearings?

By following proper installation practices, monitoring bearing health, choosing the right lubrication, and using high quality bearings like NBC.