Innovative bearing designs are redefining modern engineering. As industries move toward higher performance and increased efficiency, advanced bearing technologies are emerging as critical enablers. From automotive to aerospace, these innovations help machines run smoother, last longer, and operate more reliably—even under extreme conditions.

Today, bearings are not just mechanical components; they’re precision-engineered solutions built to meet the evolving demands of next-generation machinery.

The Evolution of Bearing Designs

Bearing technology has come a long way from its basic early forms. Initially designed simply to reduce friction, bearings have evolved into highly engineered components built for accuracy, endurance, and adaptability.

Key milestones in this evolution include:

The shift to rolling-element bearings for better efficiency

Adoption of different materials for improved durability and reduced weight

Integration of sensors for real-time monitoring and predictive maintenance

As machinery design became more complex and industries demanded higher reliability, bearing designs advanced accordingly. Today, bearings are customized to suit specific applications—from high-speed aerospace turbines to compact automotive assemblies—reflecting the diverse needs of modern engineering.

Key Innovations Driving Modern Bearing Technology

The bearing industry is experiencing unprecedented innovation, driven by performance requirements and sustainability goals.

1. Advanced Materials

Modern bearings increasingly use ceramics, composites, and engineered steels to:

Increase durability

Reduce friction

Improve resistance to heat, corrosion, and wear

2. Magnetic Bearings

Magnetic bearings eliminate physical contact by using magnetic fields, resulting in:

Zero lubrication requirements

Remarkably low friction

Extremely high-speed capability

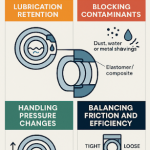

3. Hybrid & Self-Lubricating Bearings

Hybrid bearings combine ceramic rolling elements with steel races for superior performance, while self-lubricating designs reduce maintenance needs and improve operational uptime.

4. Additive Manufacturing (3D Printing)

3D printing enables high-precision prototypes and complex geometries that were previously impossible to machine.

This innovation supports faster development cycles and cost-effective customization.

Custom Bearing Designs: Precision Tailored for Industry Needs

Every industry has unique challenges, and custom-designed bearings offer the flexibility to meet them. These specialized solutions help improve performance, longevity, and reliability in applications where standard designs may fall short.

Custom bearings allow for:

Specific dimensions suited to unique machinery

Material choices based on environmental demands

Design modifications to increase load capacity or reduce friction

Advanced simulation tools play a major role in developing these solutions. Engineers model, validate, and refine designs digitally before production, ensuring high accuracy and optimal performance.

High-Performance Bearings for Extreme Conditions

High-performance bearings are engineered to thrive in challenging environments. Industries such as aerospace, automotive, defence, and heavy machinery rely on these components because failure is not an option.

Key features include:

High heat resistance

Exceptional corrosion protection

Long service life under continuous stress

Precision performance at high speeds

These bearings are often manufactured using advanced ceramics and specialized alloys to ensure minimal friction and maximum reliability.

Additionally, their energy-efficient designs support sustainability initiatives by reducing power consumption and heat generation.

Applications Across Industries

Innovative bearing designs impact a wide range of industries, each with its own operational demands.

Automotive: Bearings must withstand high speeds, heat, and variable loads to ensure safety and performance.

Aerospace: Lightweight, high-strength bearings help improve fuel efficiency and maintain flight reliability.

Manufacturing: Precision bearings support consistent product quality and efficient machine movement.

Renewable Energy: Turbines and solar tracking systems depend on robust, long-life bearing solutions.

Food & Beverage: Hygienic, corrosion-resistant bearings ensure compliance and clean operation.

Marine: Bearings support propulsion systems and withstand harsh sea conditions.

Logistics & Warehousing: Conveyor and handling equipment rely on durable, low-maintenance bearings to ensure smooth operations.

These diverse applications underline the importance of innovation across bearing technologies.

The Future of Bearing Designs

The next wave of bearing advancements will be shaped by:

Eco-friendly materials and manufacturing processes

Intelligent systems for condition monitoring

Greater adoption of smart, sensor-integrated bearings

Designs that reduce noise, friction, and energy consumption

As machines become more advanced, bearings will continue evolving to meet higher expectations for precision, reliability, and sustainability.

At NBC Bearings, innovation goes beyond design—it starts with the materials that define performance. NBC leverages a wide portfolio of high-grade alloy steels, case-hardened steels, stainless steels, and advanced ceramic hybrids to engineer bearings that perform reliably across diverse operating conditions.

From corrosion-resistant stainless steel bearings for food processing and marine environments to high-strength alloy steel bearings for railways, automotive, and heavy industries, NBC continuously invests in metallurgical research and precision heat-treatment processes. These material innovations ensure superior fatigue life, reduced wear, and consistent performance even under extreme loads, high speeds, and harsh environments.

By combining advanced materials science with indigenous R&D, NBC is setting new benchmarks in durability, efficiency, and sustainability—supporting India’s industrial growth while delivering world-class bearing solutions across global markets.