Introduction

Bearings are the unsung heroes of machinery. Whether in an industrial gearbox, a conveyor motor, or even a car wheel hub, they reduce friction, support heavy loads, and enable smooth, quiet motion. But even the best bearing can fail prematurely if the seal protecting it is compromised. Bearing seals do more than keep dirt out—they retain lubrication, block contaminants, balance pressure, and extend equipment life. Without them, maintenance teams face unplanned downtime, costly repairs, and frustrated operators. In this article, we’ll explore the world of bearing seals—their purpose, types, materials, design considerations, applications, and emerging innovations—helping you choose the right seal for maximum reliability and performance.What Exactly Is a Bearing Seal?

A bearing seal is a protective barrier that closes the gap between stationary and moving parts. Think of it as the machine’s gatekeeper: it keeps contaminants out while holding lubrication in.Seal vs Shield vs Cover:

- Seal: Elastomer or composite barrier that provides tight protection

- Shield: Thin metal plate, primarily for dust exclusion

- Cover: Protective housing for external protection

Core Functions of Bearing Seals

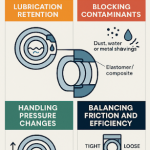

- Lubrication Retention: Keeps grease or oil inside the bearing for optimal operation

- Contaminant Protection: Blocks dust, water, and metal debris

- Pressure Handling: Balances pressure changes in compressors, fans, and rotating equipment

- Friction vs Efficiency: Tight seals offer better protection but slightly increase friction; loose seals reduce friction but are less protective

Common Types of Bearing Seals

- Contact Seals: Single-lip or multi-lip designs for robust protection

- Non-Contact Seals: Labyrinth or gap seals ideal for high-speed applications

- Shields: Metal or non-contact barriers

- Advanced Seals: Dry gas seals, magnetic seals, Teflon® seals for specialized applications

Materials That Make or Break a Seal

- Nitrile Rubber (NBR), Viton®, Silicone, PTFE (Teflon®)

- Steel reinforcements and garter springs ensure proper fit and longevity

Practical Seal Design & Assembly

Key factors include lip shape, groove fit, shaft finish, and multi-stage sealing systems. Attention to these details ensures optimal performance and minimizes the risk of early failure. Where Seals Fail:- Lip wear

- Embedded contaminants

- Heat or chemical degradation

- Misalignment

Real-World Applications

- Industrial Equipment: Gearboxes, motors, conveyors

- Automotive: Wheel hubs, transmissions, differential systems

- Energy: Turbines, compressors, pumps

- Food Processing: Seals that resist corrosion and maintain hygiene standards

- Mining conveyor: Multi-lip seals extended bearing life by 40%

- High-speed fans: Labyrinth seals reduced power losses by 8%

- Gas turbines: Dry gas seals decreased downtime by over 50%

Maintenance & Replacement Best Practices

- Inspect seals for cracks, wear, or contamination

- Replace seals when changing bearings or if damage is observed

- Ensure lubrication compatibility

- Consider retrofitting older systems for improved efficiency

- Smart Seals: Integrated sensors monitor temperature, pressure, and vibration

- Self-Healing Materials: Extend seal life under extreme conditions

- Nanocomposites: Improve durability and reduce friction

- Digital Simulation: Optimizes seal design and predicts performance

Choosing the Right Seal: Quick Checklist

- Define the operating environment (dust, moisture, chemicals)

- Decide contact vs non-contact based on speed and load

- Match the material to temperature, chemical exposure, and wear

- Follow industry codes and standards

- Balance cost vs downtime risk

Quick Takeaways

- Function = keep lubrication in, contaminants out

- Seal type depends on environment and operating speed

- Material selection is critical for durability

- Common failures stem from wear, heat, and contamination

- Emerging technologies make seals smarter, longer-lasting, and more efficient