Aerospace engineering is a realm where human ingenuity meets the vast expanse of the cosmos, propelling us beyond the realms of Earth’s atmosphere and into the unknown. It’s a journey marked by bold exploration, technological marvels, and groundbreaking discoveries.

At the heart of this cutting-edge field lie precision-engineered bearings, playing a crucial role in the smooth operation and safety of aerospace systems. From powering supersonic jets to propelling spacecraft toward distant stars, these tiny yet mighty components are the silent guardians of our skyward ambitions, navigating the cosmos with unwavering precision and reliability.

Precision Engineering for Aerospace Industry

In the annals of history, aerospace engineering has witnessed remarkable achievements that have shaped the course of human progress. From the Wright brothers’ historic first flight at Kitty Hawk to the awe-inspiring sight of astronauts walking on the moon, each milestone stands as a testament to human determination and innovation.

As we venture further into the cosmos, with SpaceX and Chandrayaan to the prospect of commercial space travel, the role of precision bearings becomes even more critical. They are the invisible threads that weave together the fabric of our aerospace dreams, ensuring that each journey is a testament to human endeavor and achievement.

Why Are Aerospace Bearings in Demand?

The soaring demand for aerospace bearings reflects the relentless pursuit of excellence in the sky-high realm of aviation. Imagine the precision needed to navigate through turbulent skies or brave the fiery reentry of a spacecraft. Here reliability, precision, and durability are paramount. Therefore an aerospace bearings must

- withstand extreme temperatures,

- sustain high speeds,

- endure heavy loads, and

- survive corrosive environments,

all while maintaining precise functionality. These aerospace bearings are meticulously engineered to meet the stringent standards of the aerospace sector, where even the slightest deviation can have catastrophic consequences.

Recent headlines have underscored the critical role of aerospace bearings in the industry’s most ambitious endeavors. From the successful landing of Mars rovers to the groundbreaking advancements in hypersonic flight, these bearings have been the backbone of countless missions, ensuring smooth operations amidst the most unforgiving environments.

Consider SpaceX’s Falcon rockets, which have revolutionized space travel with their reusable design. Behind the scenes, aerospace bearings work tirelessly to support the intricate machinery that propels these rockets into the cosmos, enabling groundbreaking achievements like the historic Crew Dragon missions to the International Space Station, or closer home with Vikram Lander and the dark side of the moon expedition successfully achieved by ISRO.

In the fast-paced world of aviation, every second counts, and the demand for aerospace bearings has never been higher. Whether it’s powering next-generation fighter jets or propelling commercial airliners across continents, these bearings are the unsung heroes of modern aviation, ensuring safety, reliability, and efficiency at every altitude.

Future of Aerospace Industry with Precision Bearings:

As the aerospace industry continues to evolve and expand, the future holds exciting possibilities for precision bearings. Advancements in materials science, manufacturing techniques, and design optimization are driving innovation in aerospace bearings, leading to lighter, stronger, and more efficient systems.

With the rise of electric propulsion, autonomous flight, and space exploration, the demand for high-performance bearings capable of operating in extreme conditions will only grow.

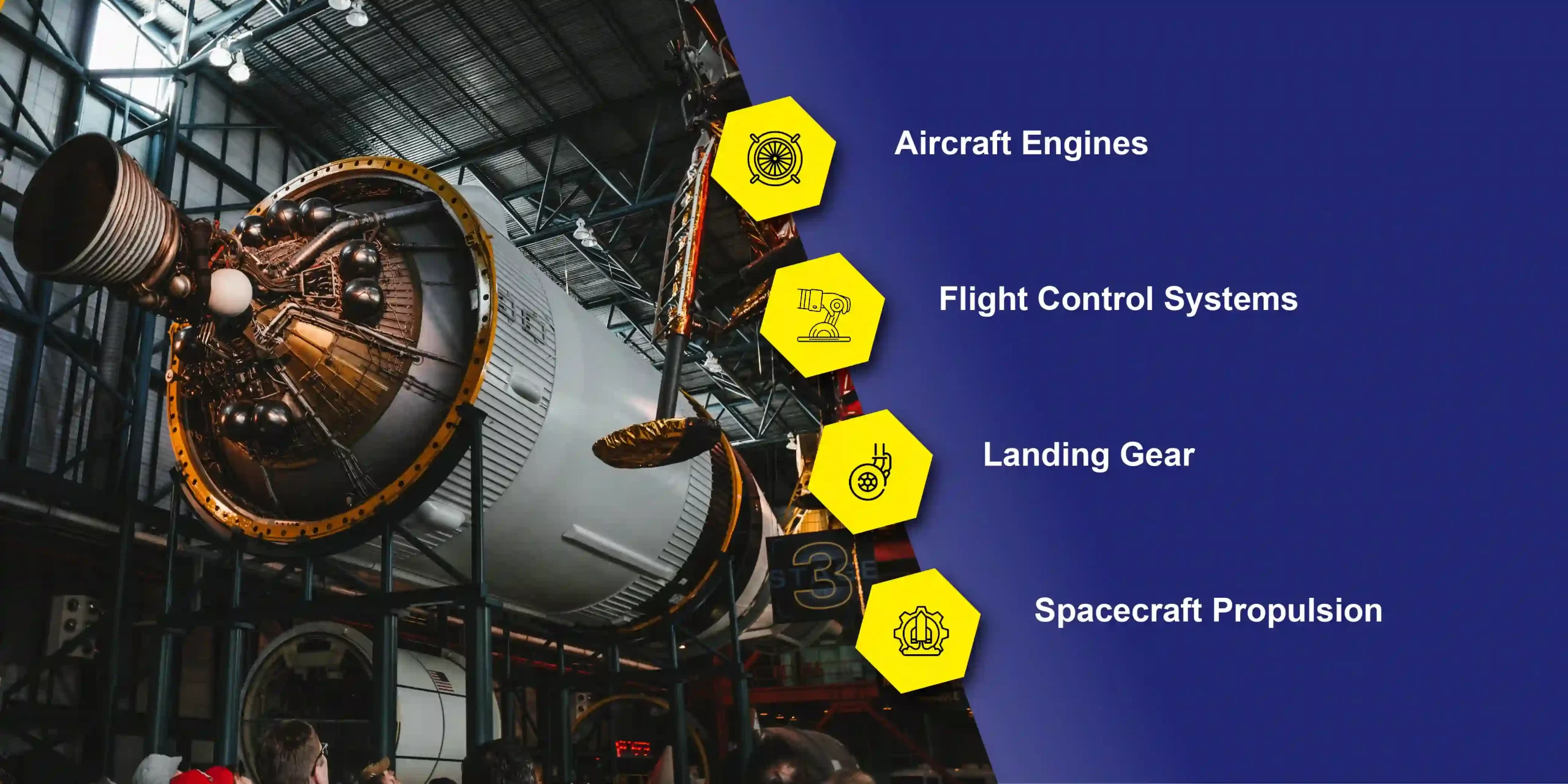

Applications of Bearings in Aerospace Engineering:

- Aircraft Engines: Bearings support rotating components such as turbine blades and shafts, contributing to engine efficiency and reliability. Commonly used products are ball bearings, roller bearings, and tapered roller bearings.

- Flight Control Systems: Bearings enable precise movement in control surfaces such as ailerons, elevators, and rudders, ensuring stable and responsive flight. Commonly used bearings in this case are: spherical plain bearings, rod end bearings, and ball bearings.

- Landing Gear: Bearings in landing gear assemblies withstand immense loads during takeoff, landing, and taxiing, providing smooth operation and structural support. Commonly used bearings in this case are: tapered roller bearings, ball bearings, and roller bearings.

- Spacecraft Propulsion: Bearings facilitate the movement of components in rocket engines and thrusters, essential for maneuvering and trajectory control. Most used bearings would be ball bearings, roller bearings, and thrust bearings.

In the dynamic and demanding world of aerospace engineering, precision bearings serve as unsung heroes, silently powering the advancement of human exploration and technology. As the aerospace industry ventures into new frontiers, from supersonic travel to interplanetary missions, the role of bearings will remain indispensable, ensuring the safety, reliability, and efficiency of aerospace systems for generations to come.

FAQ's

How do bearings contribute to aircraft engine performance?

Bearings support rotating components within aircraft engines, such as turbine blades and shafts, reducing friction and ensuring smooth operation, thereby optimizing engine performance.

What role do bearings play in aerospace flight control systems?

Bearings enable precise movement in aerospace flight control systems, ensuring stable and responsive aircraft maneuverability by facilitating the operation of control surfaces such as ailerons, elevators, and rudders.

How are bearings engineered for space exploration in spacecraft?

Bearings for space exploration are engineered to withstand the harsh conditions of space, including extreme temperatures, vacuum environments, and radiation exposure, while maintaining precise functionality for critical spacecraft systems.

Why is precision crucial in aerospace bearings?

Precision is crucial in aerospace bearings to ensure accurate alignment, minimal friction, and reliable performance under extreme conditions, ultimately contributing to the safety and efficiency of aerospace systems.

Are there specialized bearings for different aerospace applications?

Aerospace bearings must overcome challenges such as high temperatures, rapid temperature fluctuations, vacuum environments, high speeds, heavy loads, and exposure to corrosive substances, all of which can affect bearing performance and longevity.

What challenges do aerospace bearings face in extreme conditions?

Yes, aerospace bearings are tailored to specific applications and environments within the aerospace industry, with variations in materials, designs, and coatings to meet the unique requirements of aircraft engines, flight control systems, landing gear, and spacecraft propulsion systems.