Introduction

Every machine, from a car engine to an industrial press, depends on bearings to reduce friction and support moving parts. Picking the right bearing size is one of the most important decisions in machine design — and one that can save you from costly failures later on. If a bearing is too small, it will overheat or wear out too soon. If it’s too large, it wastes space, increases cost, and adds unnecessary weight. That’s where a bearing size calculator makes life easier. By entering your application’s load, speed, and working conditions, it can recommend the ideal bearing size. At NBC Bearings, one of India’s leading bearing manufacturers, engineers can now use the NBC Bearing Calculator — a simple, step-by-step digital tool that helps select the perfect bearing for any application.What Exactly Is a Bearing Size Calculator?

A bearing size calculator is an engineering tool that uses data like load, speed, temperature, and lubrication to calculate the bearing’s dynamic equivalent load and expected life (L10). Traditionally, these calculations were done manually using formulas from the ISO 281 standard — a time-consuming process. The main equation combines both radial and axial forces into one value using: P = X·Fr + Y·Fa Here, Fr is the radial load, Fa is the axial load, and X and Y are correction factors based on the bearing type. NBC’s calculator automates this entire process. It pulls data directly from NBC’s product catalogue, performs the calculations instantly, and gives you reliable results without the manual math.Why Getting the Size Right Matters

Choosing the correct bearing size affects everything — from performance to safety.- Longer service life: A properly sized bearing avoids fatigue, cracking, and early wear.

- Better efficiency: The right fit minimizes friction and power loss.

- Less downtime: Mismatched bearings cause heat, noise, and vibration, which can lead to breakdowns.

- Improved safety: Especially in heavy machinery, the wrong bearing size can create serious risks.

Understanding Bearing Codes and Dimensions

Bearings may look simple, but their numbers tell a complete story. Each bearing code contains details about its size and type.- Prefix: Identifies special versions or components.

- First digit: Shows the bearing type (like deep groove, thrust, or roller).

- Second digit: Indicates the series — light, medium, or heavy — which relates to load capacity.

- Third and fourth digits: Represent the bore diameter in millimetres.

- Suffix: Describes design details such as seals, clearance, or cage type.

How the NBC Bearing Calculator Works

The NBC Bearing Calculator walks you through two simple stages:Step 1: Select a Bearing

You can either:- Search by part number if you already know the bearing you need, or

- Browse from a list of bearing types such as Deep Groove Ball Bearings, Angular Contact Bearings, or Tapered Roller Bearings.

Step 2: Enter Your Application Data

Next, enter a few details about your working conditions:- Radial and axial loads (Fr and Fa) – in kilonewtons. The calculator automatically applies the load equation.

- Rotational speed (n) – in RPM.

- Operating temperature – since higher temperatures affect material strength.

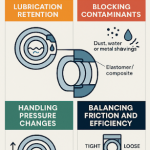

- Lubrication type and viscosity – choose between oil or grease.

- Contamination level – define how clean or dusty the environment is.

- Reliability factor (a1) – select the reliability percentage you want (90%, 95%, or 99%).

Interpreting the Results

The results page gives you a clear picture of how the bearing will perform:- Dynamic equivalent load (P): The combined effect of all forces on the bearing.

- Basic dynamic load rating (C): The load a bearing can handle for one million revolutions.

- Bearing life (L10 or L10h): Calculated using standard ISO 281 formulas.

- Adjusted life (Lnm): Accounts for reliability and environmental conditions.

Tips for Accurate Results

To get the best out of your bearing calculations:- Measure bore, outer diameter, and width carefully using precise tools.

- Use real load data, not just theoretical values.

- Factor in speed, lubrication, and temperature accurately.

- Always check bearing clearance — it affects performance and heat buildup.

- Consider contamination levels and use the right protective measures.

- Stick to industry best practices when measuring, recording, and selecting bearings.