Introduction

Smooth, precise motion is at the heart of modern machinery — whether it’s a CNC milling center, a robotic arm, or even a 3D printer. Behind the scenes, ball bearings quietly make this possible. While often associated with rotating shafts and wheels, ball bearings are just as critical in linear motion systems, ensuring machine tables glide effortlessly, gantries stay aligned, and actuators deliver repeatable accuracy. In this article, we’ll explore the fundamentals of ball bearings, their role in linear motion, design considerations, common challenges, and emerging technologies. Whether you’re an engineer, technician, or machinery enthusiast, this guide provides practical insights to help you maximize performance, reliability, and efficiency.Ball Bearing: The Fundamentals

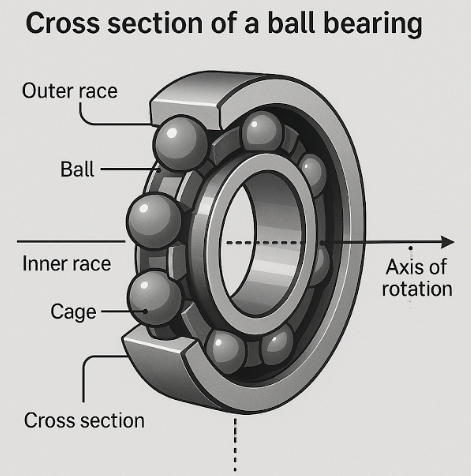

A ball bearing is a type of rolling-element bearing where hardened balls roll between two races, replacing sliding friction with rolling friction. This drastically reduces energy losses and wear while enabling precise motion.Main Components:

- Inner race: Mounted on the shaft

- Outer race: Fixed in the housing

- Balls: Rolling elements that carry the load

- Cage (retainer): Keeps balls evenly spaced

Principle of Operation:

The balls roll along the raceways, allowing shafts or housings to move or slide under load with minimal resistance. In linear motion, this principle ensures smooth, low-friction travel and high repeatability.Common Types of Ball Bearings:

- Deep Groove Ball Bearings: Standard radial load support

- Angular Contact Ball Bearings: Handles radial and axial loads

- Thrust Ball Bearings: For pure axial loads

- self-aligning Ball Bearings: Compensates for misalignment

Load Handling & Performance Metrics

Ball bearings are rated and selected based on:- Load Types: Radial (perpendicular to the shaft), axial (along the shaft), or combined loads

- Static & Dynamic Ratings: Maximum loads bearings can handle without damage, both stationary and in motion

- Life Expectancy: L10 formula predicts lifespan under specific load and speed conditions

- Speed & Heat: Friction increases at high speeds; bearings have speed limits to prevent lubrication breakdown

Materials, Precision & Lubrication

Materials:

- Chrome steel: Standard durability

- Stainless steel: Corrosion-resistant, ideal for chemical or food environments

- Ceramic & hybrids: Lightweight, stiff, high-speed capable

Precision & Hardness:

- Smooth finishes reduce wear, and hardened surfaces resist fatigue.

- Tolerance grades (ABEC/ISO) ensure micron-level accuracy in linear guides.

Lubrication & Seals:

- Lubrication reduces wear; seals prevent contamination.

- Linear bearings often have built-in grease channels for even distribution along raceways.

Why Ball Bearings Are Ideal for Linear Motion

Compared to plain bushings:

- Lower friction: Smooth travel with less force

- High repeatability: Precision in CNC, robotics, and actuators

- Energy efficiency: Reduced drive power required

- Extended service life: With proper care

Linear Motion Systems Using Ball Bearings

- Recirculating Linear Ball Bearings (Ball Bushings): Cylindrical housings with recirculating balls, commonly used in 3D printers, lab automation, and pick-and-place robots.

- Linear Ball Slides (Carriages on Rails): Provide high rigidity and precision; essential in CNC machine tools.

- Ball Screws: Convert rotary motion into precise linear motion; widely used in actuators and machine tables.

- Ball Splines: Allow linear movement while transmitting torque; ideal for robotics and automation.

How They Work:

Balls recirculate through load zones and return paths, allowing theoretically unlimited travel. Preload eliminates play for higher stiffness, while alignment and parallelism of rails are critical to avoid uneven load and premature wear. Multiple ball rows share loads to maintain rigidity in all directions.Design Considerations & Selection

When choosing linear ball bearings, consider:

- Load Capacity: Match dynamic ratings to expected forces

- Speed & Friction: High-speed systems require low-friction designs

- Accuracy & Rigidity: Critical for CNC tools and precision equipment

- Environment: Sealed bearings for dusty factories; lubrication-free for cleanrooms

- Preload & Clearance: Balance smooth motion with stiffness

- Life Calculations: Estimate operating life using distance-based formulas

Practical Applications & Case Studies

- CNC Machine Tools: Accuracy depends on preloaded carriages and ball screws.

- 3D Printers: Ball bushings on guide shafts enable smooth gantry movement.

- Robotic Arms: Ball screws provide precise, repeatable actuation.

- Medical Equipment: Miniature linear bearings enable silent, precise motion in diagnostic machines.

Common Failure Modes & Maintenance

Failures often include:

- Wear / Brinelling: Indentations from overload

- Fatigue Spalling: Flaking due to repeated stress

- Misalignment: Causes uneven load and noise

- Lubrication failure: Accelerates wear

- Blockage in recirculation: Stops smooth motion

Maintenance Tips:

- Inspect regularly for noise, vibration, or rough travel

- Re-lubricate according to operating hours; automated lube systems help

- Replace damaged bearings promptly

- Consider retrofitting older systems with modern linear ball guides for higher accuracy and efficiency

Emerging Trends & Innovations

- Ceramic & Hybrid Bearings: Lighter, stiffer, longer-lasting

- Smart Bearings: Integrated sensors monitor vibration, load, and temperature in real-time

- Nano-Coatings: Reduce friction and enhance corrosion resistance

- 3D-Printed Housings: Lightweight, customizable solutions for specialized machinery