In the aerospace industry, every component matters. Whether it’s a commercial jet, a military aircraft, or a space-bound system, precision and reliability are non-negotiable. Among the countless parts that keep an aircraft safe and efficient, engineered bearings play a quiet but extraordinary role. They support smooth movement, manage extreme loads, and ensure critical systems function exactly as intended — every single time.

For NBC Bearings, delivering world-class aerospace bearings isn’t just engineering. It’s a commitment to safety, performance, and the future of aviation.

Why Aerospace Bearings Matter

Aircraft systems operate in conditions far tougher than any industrial environment. Bearings must perform reliably under:

- Extreme temperatures inside engines

- High dynamic loads during takeoff, landing, and turbulence

- High-speed rotations in turbines and actuators

- Severe vibrations across the airframe

Standard bearings simply cannot survive these conditions. Aerospace bearings, however, are engineered with specialized materials, coatings, and manufacturing precision to maintain stability and performance in the harshest environments.

How Bearings Influence Aircraft Performance

1. Reliability in Critical Systems

Aerospace bearings directly support essential functions such as:

- Engine and turbine operation

- Flight controls (ailerons, elevators, rudders)

- Actuation systems

- Landing gear deployment

- Navigation and instrumentation

A single bearing malfunction can compromise safety. Robust bearing performance ensures reliability throughout the aircraft’s life cycle.

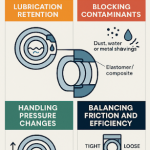

2. Reduced Friction & Improved Fuel Efficiency

Efficient bearings minimize friction across rotating parts, resulting in:

- Better fuel economy

- Lower heat generation

- Reduced wear and tear

- Longer service intervals

In an industry where every kilogram of fuel matters, this advantage is significant.

3. Lightweight Yet High-Strength Engineering

Modern aerospace design prioritizes lower weight without compromising strength. Engineered bearings balance high load-carrying capacity with lightweight construction, supporting overall aircraft efficiency.

Where Aerospace Bearings Are Used

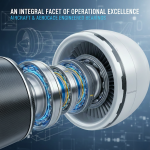

1. Aircraft Engines

Bearings in engines face the most punishing conditions. They are used in:

- Turbofan and turboprop engines

- Turbochargers

- Auxiliary Power Units (APUs)

They ensure high-speed stability, manage extreme temperatures, and reduce vibration within the turbine assembly.

2. Flight Control Systems

Precision bearings support the smooth and responsive movement of:

- Ailerons

- Elevators

- Rudders

Their low-friction design ensures accurate pilot control and aircraft stability.

3. Landing Gear

Landing gear bearings must handle:

- Massive impact forces on touchdown

- Abrupt acceleration and deceleration

- Corrosion from environmental exposure

Special coatings and materials ensure durability and consistent performance.

4. Actuation Systems

Bearings in electromechanical and hydraulic actuators support:

- Flap and slat deployment

- Brake systems

- Gearbox components

In these systems, even the slightest tolerance variation can affect safety, making precision essential.

5. Cabin & Auxiliary Systems

Even non-flight-critical systems rely on engineered bearings, including:

- Seating assemblies

- Air-conditioning units

- Cargo handling mechanisms

These ensure operational comfort and overall aircraft efficiency.

Engineering That Sets Aerospace Bearings Apart

1. Advanced Materials

To survive extreme conditions, aerospace bearings commonly use:

- High-chromium steel

- M50 tool steel

- Titanium alloys

- Ceramic balls (in hybrid bearings)

These materials offer superior hardness, corrosion resistance, and fatigue strength.

2. Performance-Enhancing Coatings

Cutting-edge coatings boost durability and reduce lubrication needs:

- PTFE / MoS? coatings for low friction

- Chrome or DLC coatings for wear resistance

- Anti-corrosion layers for longevity

3. Precision Manufacturing

Aerospace bearings undergo:

- Ultra-fine grinding

- Micron-level machining

- Rigorous balancing tests

- High-precision heat treatment

The result: unmatched accuracy and reliability.

4. Global-Standard Quality Testing

Aerospace bearings must meet stringent certifications such as:

- AS9100

- NADCAP

- FAA / EASA requirements

Every bearing is tested for performance, safety, and traceability.

NBC Bearings: Advancing India’s Aerospace Capability

As one of India’s leading bearing manufacturers, NBC Bearings has built deep expertise in high-precision applications for the aerospace sector.

Our Strengths:

- Specialized aerospace-grade ball, roller, spherical, engine, and actuator bearings

- State-of-the-art R&D and simulation-based design

- Strong metallurgical competence and advanced testing facilities

- Customized solutions for OEMs based on load, temperature, and life-cycle needs

- Zero-defect deliveries through global-quality processes

NBC’s engineering excellence makes it a trusted partner for both domestic and global aerospace manufacturers.

Driving Operational Excellence in the Sky

As aircraft become more advanced — with electrification, automation, and lightweight engineering — the role of precision bearings becomes even more crucial. Their influence extends far beyond mechanical rotation: they impact sustainability, safety, efficiency, and operational longevity.

At NBC Bearings, we are committed to delivering aerospace-grade components that meet the highest global standards — supporting safer skies and future-ready flight systems.

Conclusion

Engineered aerospace bearings are far more than mechanical parts. They are silent enablers of flight safety, fuel efficiency, and operational excellence. Their ability to operate flawlessly under extreme conditions makes them indispensable in the aviation ecosystem.

With robust engineering, cutting-edge technology, and a legacy of precision, NBC Bearings continues to strengthen India’s foothold in global aerospace manufacturing — ensuring performance you can trust, flight after flight.