Tag: sensor bearings

Want to know about sensor bearing and how it is used in place of conventional bearing? Here in this blog, we will look at everything that you need to know about sensor bearings.

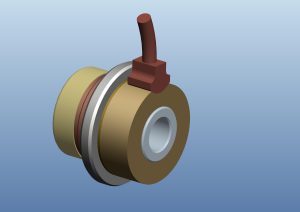

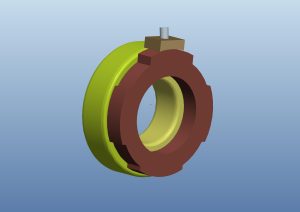

Sensor bearings are mechatronic bearings that feature a bearing and a sensor housed together. In these bearings, Harem Hall sensors are used to convert signals to electronically readable data. When the bearing rotates, the sensor in the sensor bearing measures the bearing speed and direction which is converted into electronic data to assist in optimized performance and results. NBC has developed the sensor bearing as an alternative standalone sensor to make the bearings smarter and optimized for high-performing applications.

Sensors Bearings are a type of bearings integrated with Harem Hall sensors to convert signals from bearings into electronic data.