Over the years, there has been a rise in the demand for sensor bearing, and the primary reason is its use in the wheels and rotating shafts of automobiles. However, its usage is just not limited to the automotive industry as it can also be used in electric motors in various industries.

The use of sensors helps measure the wheel’s circumferential speed, the direction of rotation, acceleration, and deceleration. As far as the design is concerned, it has a simple and compact structure and occupies significantly less space and weight, making it a cost-effective alternative to conventional solutions.

In addition to the points mentioned above, there are many features that make sensor bearing the smartest of all. This article will take you through all that you need to know about NBC sensor bearings and how it is opening a new door to research and development possibilities.

Sensor Bearings - Design Feature, And Principle

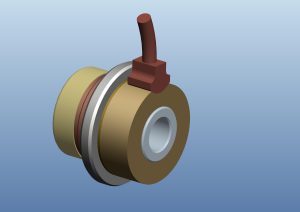

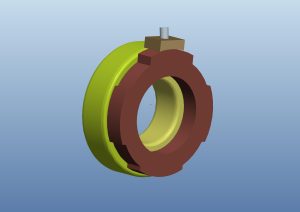

The design is a combination of high precision bearing with sensor technology. NBC sensor bearing is made of:

- A standard deep groove ball bearing with a seal on one side and a snap ring

- Sensor

- Magnetized encoder ring

- Connecter, i.e., a connecting cable

The magnetized encoder is attached to the inner ring of the bearing, which is mounted on the shaft of the electric motor/ two-wheeler. As the magnetized inner ring rotates past the outer ring, the magnetic field of changing polarity is generated.

The sensor attached to the outer ring transmits the signal to the controller via connecting cable in response to the change in polarity per second. The signal can be processed to generate the required information.

Right now, we are in the stage of offering sensor bearings for two applications:

Sensor Bearings For Two-Wheelers

A modern substitute for a mechanical toner ring that optimizes the two-wheeler’s performance by providing instantaneous feedback to the controller and anti-lock braking systems (ABS) for better efficiency and controllability, especially in electrically propelled vehicles.

Features:

- Integrated two-part sub assembly for easy fitment in the hub

- Measures speed and direction of rotor position

- Torque Management in electric Propelled vehicles

Benefits:

- As a unitized complete solution, it provides more reliability, accuracy, and durability

- Eliminates usage of mechanical toner ring and toner ring sensor in the wheel

- The precise output signal (speed and direction) can be used for torque management and ABS control

- Compact & integrated solution that reduces OEM’s efforts in procurement and fitment of child parts

Application: Electric Vehicles (2W, 3W, 4W) and high-end IC engines 2W

Sensor Bearings For Motors

The sensors are integrated within the bearing unit to measure critical parameters like shaft speed (RPM), the direction of rotation, and temperature. They are compact, reliable, simple, and ready to mount.

Moreover, it is an integrated solution provided to the user for greater accuracy and precision: even the slightest rotary motion can be monitored with this bearing.

Features:

- High speed, low torque, and low noise bearing

- Integrated with sensors capable to measure

- Speed up to 15,000 RPM

- The direction of rotation (CW or CCW)

- Temperature from -30C to 125C

- Equipped with reverse polarity, over-voltage & current protection

- EMI/EMC compliant with ingress protection grade of IP67

Benefits:

- Compact & robust design yielding reliable results and ready to use

- Generates quadrature wave-form pulses flawlessly read by the controller

- Onboard condition monitoring of system

- Hassle-free & integrated solution for EV OEM

Applications: Forklifts, Tractors, Conveyors, Electric motors, and High-precision robotic arms