When adventure is the question, KTM 390 Adventure is the answer. Tall at the front, tall at the seat, and a luggage rack at the rear – all that makes it an ADV. But it doesn’t stop here, there’s more to it, from being lightweight to producing 46 BHP of power, making it the best middleweight bike for off-roading.

KTM (Kraftfahrzeuge Trunkenpolz Mattighofen), is a European motorcycle brand based out of Austria. Bajaj Auto and KTM together manufacture the KTM 390 Adventure series in India, the Philippines, and Argentina. Known for their signature colours (orange and black) KTM is recognised for their ready-to-race philosophy, innovative engineering, and high-performance off-road & street bikes.

KTM 390 Adventure’s design is inspired by KTM’s rally bikes, with a sharp LED headlamp, tall adjustable windscreen, split seat setup, slim fuel tank design, LED tail light, and comes in bold KTM graphics with signature themes. The KTM’s 390 Adventure series uses a steel trellis frame with a bolted sub-frame, aluminium swingarm, and tough plastic panels, making it a reliable option.

KTM 390 Adventure Specifications

| Category | Specifications |

| Engine | 398.63 cc |

| Power | 46 PS |

| Torque | 39 Nm |

| Frame | Steel Trellis Frame |

| ABS | Dual-Channel – cornering ABS, off-road ABS |

| Seat Height | 855mm |

| Mileage | 28-32 km/l (Approx) |

Features and Technology - The KTM 390 Adventure

KTM 390 Adventure is widely known for its powerful engine and advanced electronics. Among the many features and cutting-edge technology that make the KTM 390 Adventure perfect for both city rides and adventure touring are the following:

TFT Digital Display with Smartphone Connectivity

The 390 adventure comes equipped with a 5-inch TFT (Thin Film Transistor) screen. TFT display is a type of LCD display, widely used for its colour accuracy, brightness, and sharpness. The TFT display on the KTM 390 Adventure shows speed, RPM, fuel level, trip data, etc. Additionally, the display consists of bluetooth connectivity and seamlessly connects with smartphones for call alerts, navigation, and music control. The display can be connected through the KTM connect app. The information displayed includes:

- Fuel Gauge & Range Estimation

- Gear Position Indicator

- Clock & Temperature

- Odometer & Trip Meter

- Turn-by-Turn Navigation

- Call & SMS Notification

Ride-by-wire Throttle

The KTM Adventure 390 is equipped with ride-by-wire technology for throttle. The system uses electric wires and sensors to control the throttle of the vehicle instead of cables. Ride-by-wire technology ensures a smoother ride, better fuel efficiency, and better performance.

Traction Control

KTM’s 390 adventure series comes with MTC (motorcycle traction control). An electronic safety feature that prevents the rear wheel from losing grip. Traction control on the KTM 390 Adventure is equipped with switchable traction control, lean-sensitive traction control, and off-road mode.

Switchable ABS for Better Handling

The Adventurer comes with dual-channel ABS (Anti-lock Braking System). ABS helps prevent wheel lock-ups and enhances the safety of wet and slippery roads. The motorbike comes with switchable ABS, cornering ABS, and off-road ABS mode making it the most advanced in its segment.

Slipper Clutch

The 390 Adventure is equipped with a slipper clutch enhancing performance and safety during riding. The slipper clutch prevents the rear wheel from locking up, enhancing stability, and providing smoother gear changes.

Quick-shifter

The 390 Adventure comes fitted with a quick shifter that allows for clutchless gear changes, faster acceleration, and smoother downshift resulting in less rider fatigue.

Touring Capabilities and Comfort

The KTM 390 Adventure is considered a great touring bike and the credit goes to the upright seating position, wide handlebars, and a well-padded seat. The adventurer comes with a powerful engine, enough for highway speed and overtaking, a large 14.5-litre tank leading to fewer fuel stops, long travel suspension for rough roads and bad terrains. The adjustable windscreen reduces windblast enhancing the touring experience on the highways.

The KTM 390 Adventure is considered a tourer-friendly bike for the following reasons:

- High Ground Clearance: To tackle bad roads and off-road detours.

- TFT Display: The turn-by-turn navigation helps and allows you to focus on the ride rather than directions.

- Touring Accessories: The 390 Adventure can be equipped with luggage racks, panniers, crash guards, and auxiliary lights to aid with long-distance travel.

- WP APEX Rear Monoshock:Absorbs shocks and bumps and keeps the bike stable on rough roads.

The KTM 390 Adventure is a versatile, lightweight, and featured-packed bike. Additionally, the KTM 390 adventure accessories like a saddle bag, panniers, auxiliary lights, wider foot pegs, etc add to the touring capabilities.

Importance of Bearings in Adventure Motorcycles

Bearings play an essential role in adventure motorcycles and help ensure:

- Smoother Operation

- Stability

- Durability

Adventure motorcycles are equipped with a variety of bearings including, ball bearings, roller bearings, needle roller bearings, and more. Essentially used for reducing friction in rotating parts, including the engine, transmission, wheels, etc. Motorcycles contain around 20-30 bearings depending on their function and location within the bike.

Key Role Bearings Play in Adventure Motorcycles

- Reduce Friction: Bearings specifically ball bearings and roller bearings in adventure motorcycles reduce friction by providing a smooth, contact surface between the moving parts. Adventure motorcycles like the KTM 390 Adventure are meant to endure rough terrains, heavy loads, and long rides and thus require components to rotate with minimal resistance.

- Load Support: Adventure motorcycles are typically built to support heavy loads including the weight of crash guards, saddle bags, passengers and extra accessories. Bearings must be able to handle these high-stress requirements to maintain durability and performance when carrying this load over long distances. Adventure motorcycles are fitted with plain bearings, groove ball bearings and needle roller bearings to support load, distribute heavy loads and enhance handling and stability.

- Improves Handling: Bearings like tapered roller bearings, sealed deep groove bearings, needle roller bearings, and more are typically used in adventure motorcycles for enhancing the overall ride experience, especially through rough terrains, carrying luggage, etc. Bearing plays a crucial role in improving handling in adventure motorcycles by preventing wobbles during high speed, improving precision when cornering, and reducing head shake during tough terrains.

Some of the Commonly used Bearings in Adventure Motorcycles

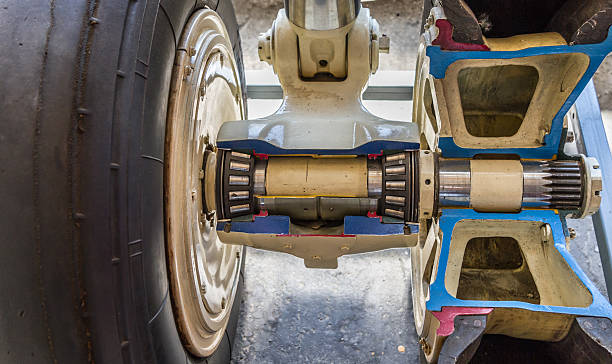

Wheel Bearings

Wheel bearings in motorcycles are used to allow the wheels to rotate smoothly, reduce friction, and support the motorcycle’s weight thus contributing to the overall ride experience. Sealed Ball Bearings re commonly used as wheel bearings to endure high loads, impact forces, and harsh riding conditions. Now, when it comes to wheel bearings for adventure motorcycles the bearings must withstand high impacts, high loads, and exposure to dirt, water, and mud. These small but crucial components are usually installed inside the wheel hub and support both radial and axial forces. Deep groove ball bearings and tapered roller bearings are commonly used in adventure motorcycles to endure off-road durability.

Steering Head Bearings

Steering head bearings are crucial components in adventure motorcycles. Especially during tough terrains and off-road conditions a high-quality steering head bearing ensures smooth steering, stability, and control and allows the handle to turn freely regardless of the forces from braking, cornering, or rough terrains. The most commonly used steering head bearings used in adventure motorcycles include:

- Tapered Roller Bearings (To handle both radial & axial loads)

- Ball Bearings (For smooth steering experience)

Steering head bearings, especially tapered roller bearings help maintain precise handling, stronger braking support, and better off-road control.

Swingarm Bearings

A swingarm, also known as a swing fork is a mechanical component that connects the rear wheel to the body of the motorcycle. Swingarms in adventure motorcycles play an important role in rear wheel suspension, overall stability, and handling. The commonly used swingarm bearings in adventure motorcycles include:

- Needle Roller Bearings (Preferred for their handling of high radial loads)

- Plain Busing (Known for simple design & lower maintenance)

Swingarm bearings assist with improved suspension action, absorbing bumps, and ensuring proper power delivery to the rear wheel.

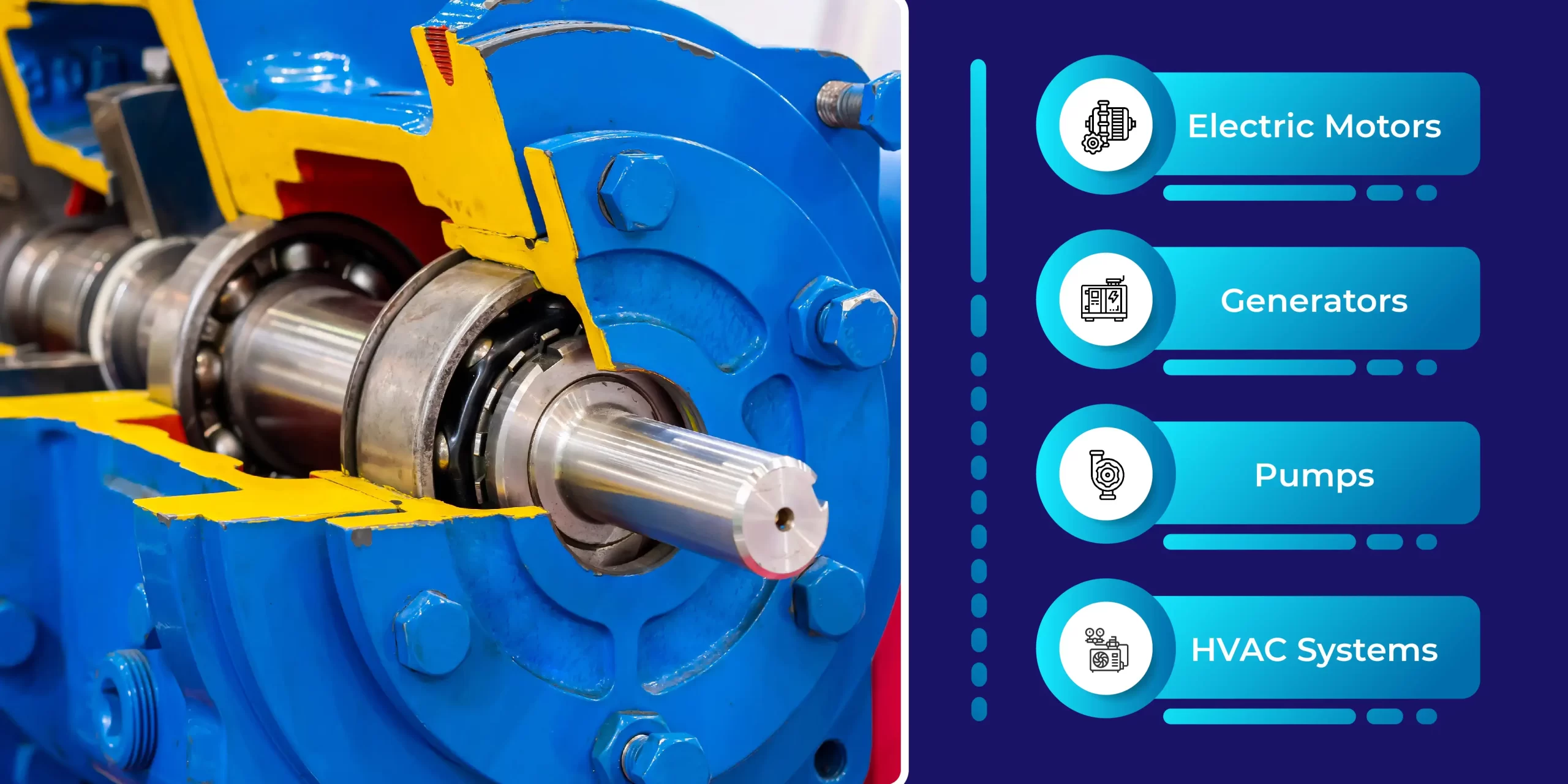

Engine Bearings

Engines are the most important component of any motorcycle be it an adventurer, cruiser, or a daily commuter and to ensure a smooth engine operation bearings have a crucial role to play. The thump you feel or the smoothness you admire which makes you like a motorcycle are affected by the smooth operation of the bearings fitted.

In adventure motorcycles like the KTM 390 Adventure, the bearings in the engine must withstand high RPMs (Revolutions per minute), extreme temperatures, and long-distance stress. These bearings are high-precision components used to reduce friction and support rotating parts inside of the engine. Some of the most commonly used engine bearings include:

- Plain Bearings (Crankshafts, connecting rods)

- Needle Roller Bearings (Gearbox shaft, clutch)

- Ball & Roller Bearings (Gearbox, alternators)

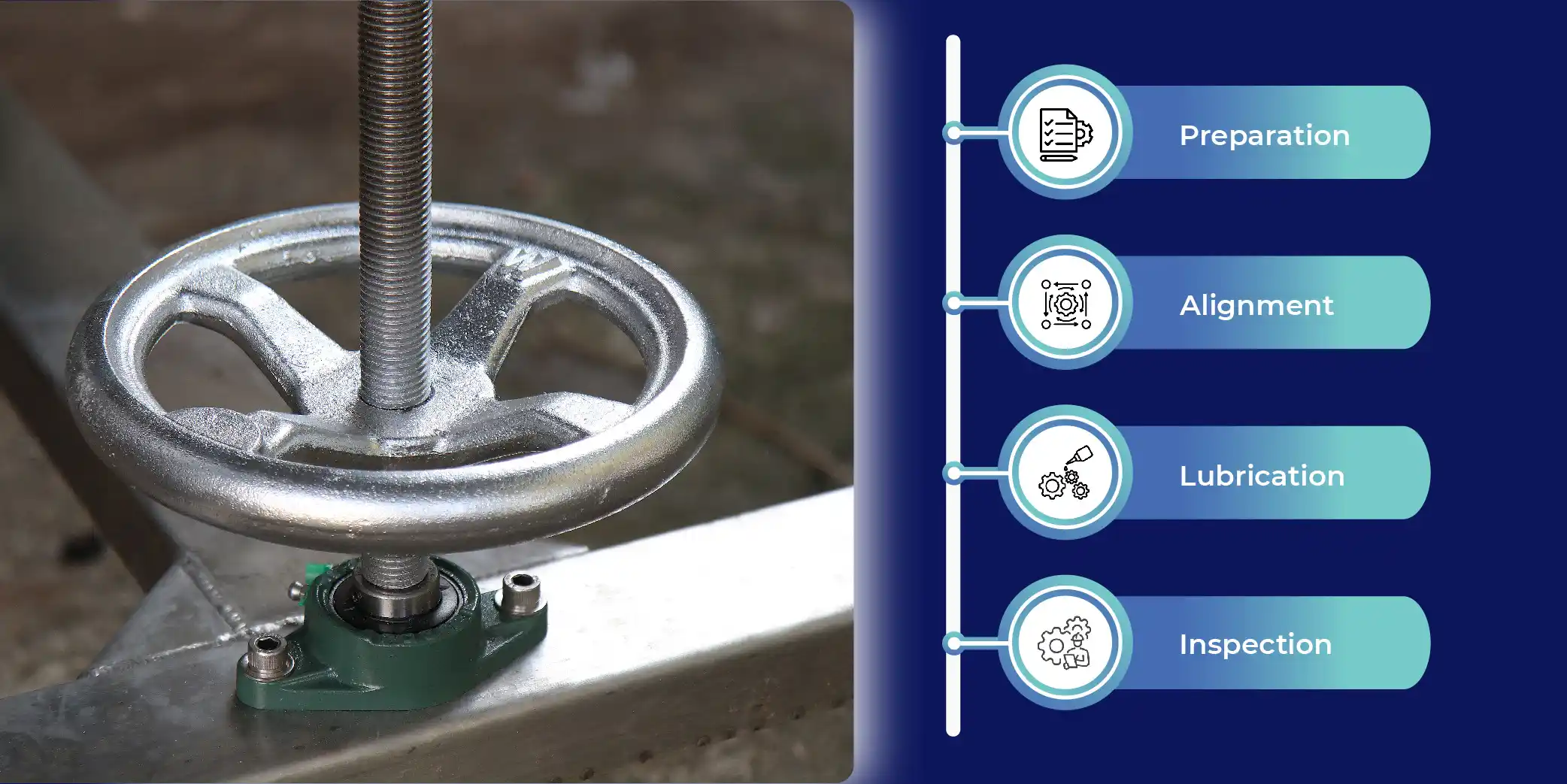

Maintenance of Bearings in Adventure Motorcycles

- Inspection: Regular inspection is the key, check for rough movements, and grinding noises around the wheels, swingarms, and other rotating components to detect the need for lubrication, maintenance, or replacement.

- Lubrication: Grease or lubricate the bearings as per the recommended kilometres mentioned on the user manual or manufacturers guide. Use waterproof grease for better protection & longevity.

- Cleaning: Keeping the bearings & other important components in an adventure motorcycle is important, especially after off-road rides. Clear the mud, dust, and water residue to ensure the bearing’s durability.

FAQ's

What are the KTM 390 Adventure bike specifications?

KTM 390 Adventure comes with a 398.63 cc single-cylinder engine producing 46 PS of power 39 Nm of torque. The motorcycle comes with a TFT display with bluetooth connectivity.

What is the power of the KTM 390 Adventure?

The KTM 390 Adventure produces 46 PS of power & 39 Nm of torque.

How fast will a KTM 390 Adventure go?

The 6-speed engine is known to go up to 155 km/h (approx) of speed.

What is the mileage of 390 Adventure?

The 390 Adventure provides a mileage of around 28-32 km/l (approx).