Types of Bearings in Paper Industry

There are various types of bearings used in the paper printing industry, including:- Deep groves ball bearings: The most popular bearings in paper industry are deep groove ball bearings. They are perfect for the paper feeding system since they withstand high temperatures and speeds.

- Angular contact ball bearings: Because they can support both radial and axial loads, they are perfect for applications where the load is not solely radial. They are frequently utilized in the printing cylinder and other precise sections of the printing press.

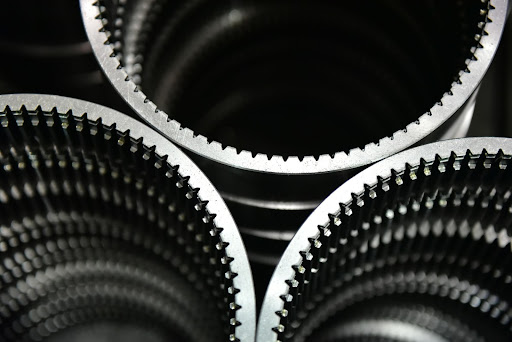

- Cylindrical roller bearings: These are frequently utilized in the printing press’s impression cylinder and other components that need to carry heavy loads.

- Spherical roller bearings: These bearings are perfect for applications where misalignment is a concern. They are frequently utilized in the ink fountain and other printing press parts because they can support both radial and axial stresses.

- Needle roller bearings: These bearings have a narrow cross-section and are made to withstand heavy radial stresses. They are frequently utilized in the ink roller and other restricted-space sections of the printing machine.

Role of Bearings in the paper industry

The paper printing business relies heavily on bearings. To ensure that numerous components move smoothly and precisely, bearings are significantly used in paper printing machines. The paper feeding system is one crucial area where bearings are used. The printing press receives a constant paper supply thanks to the paper-feeding mechanism. The paper rolls are supported by bearings, ensuring smooth, vibration-free movement. The printing cylinder is another essential application for bearings. Ink is transferred from the printing plate to the paper via the cylinder. For high-quality printing, the cylinder must rotate precisely and smoothly, which is ensured by bearings in this region. Bearings are also utilized in the ink fountain, ink roller, and impression cylinder, in addition to these locations, in the printing press. Bearings assist in lowering friction, absorbing shock, and ensuring correct movement in each area. Overall, using bearings in the paper printing business is essential for producing prints of the highest quality. Bearings guarantee that the printing press runs smoothly and precisely, producing high-quality printed materials.Why can you trust NBC Bearings?

Leading Indian bearing maker NBC (National Engineering Industries Ltd.) has a long history of producing high-quality bearings. The paper industry may benefit from selecting NBC bearings for the reasons listed below:- High-quality standards: NBC bearings are produced in accordance with global quality standards, guaranteeing dependable performance. They go through stringent testing and quality control procedures to ensure they adhere to the strict standards of the paper industry.

- Customization: The unique needs of the paper industry, such as high-speed applications, high-temperature settings, and load-carrying solid capability, can be met by tailoring NBC bearings.

- Technical know-how: NBC has a team of skilled experts who can offer technical support and help decide which bearing is best for a given application. They can assist in enhancing the printing press’s efficiency because they have an in-depth understanding of the paper business.

- Longevity: NBC bearings are made to survive the demanding operating conditions in the paper industry, such as high temperatures, heavy loads, and rapid speeds. They are constructed with premium materials and undergo rigorous quality control procedures to ensure their sturdiness and lifespan.

- Cost-effectiveness: With competitive prices and little maintenance needs, NBC bearings provide a cost-effective solution for the paper sector. They have a long service life, which minimizes downtime and lessens the need for frequent replacements.