In the world of machinery and mechanical engineering, bearings play a crucial role in facilitating smooth motion and reducing friction. However, like any other component, bearings have a finite lifespan and go through various stages in their life cycle. Understanding these stages and knowing how to navigate them effectively is essential for maximizing efficiency and prolonging the life of bearings.

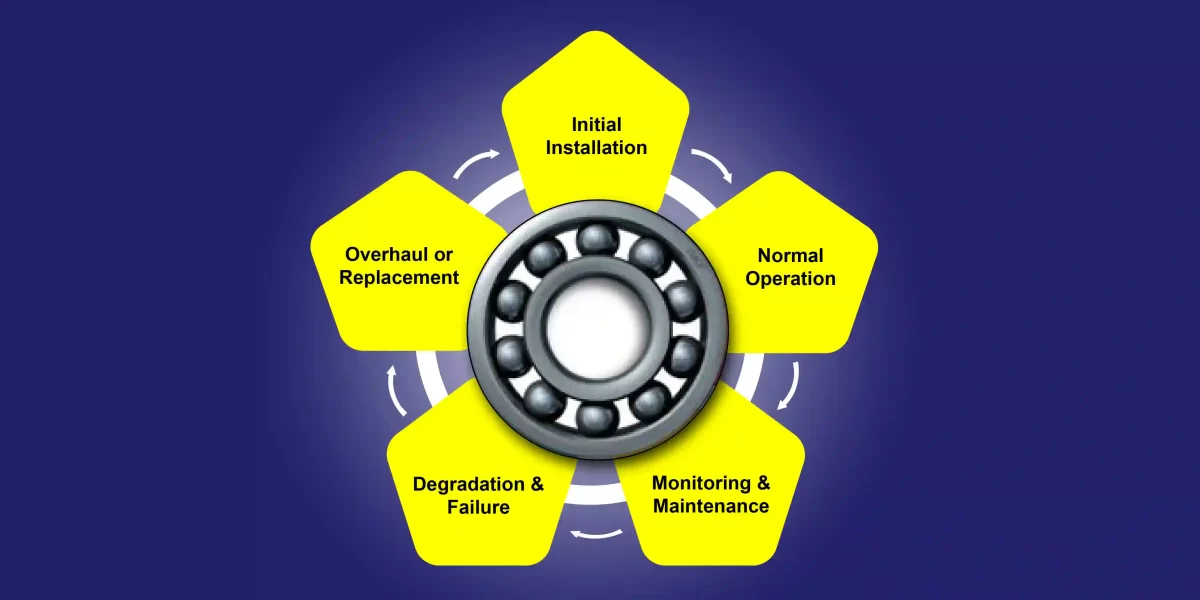

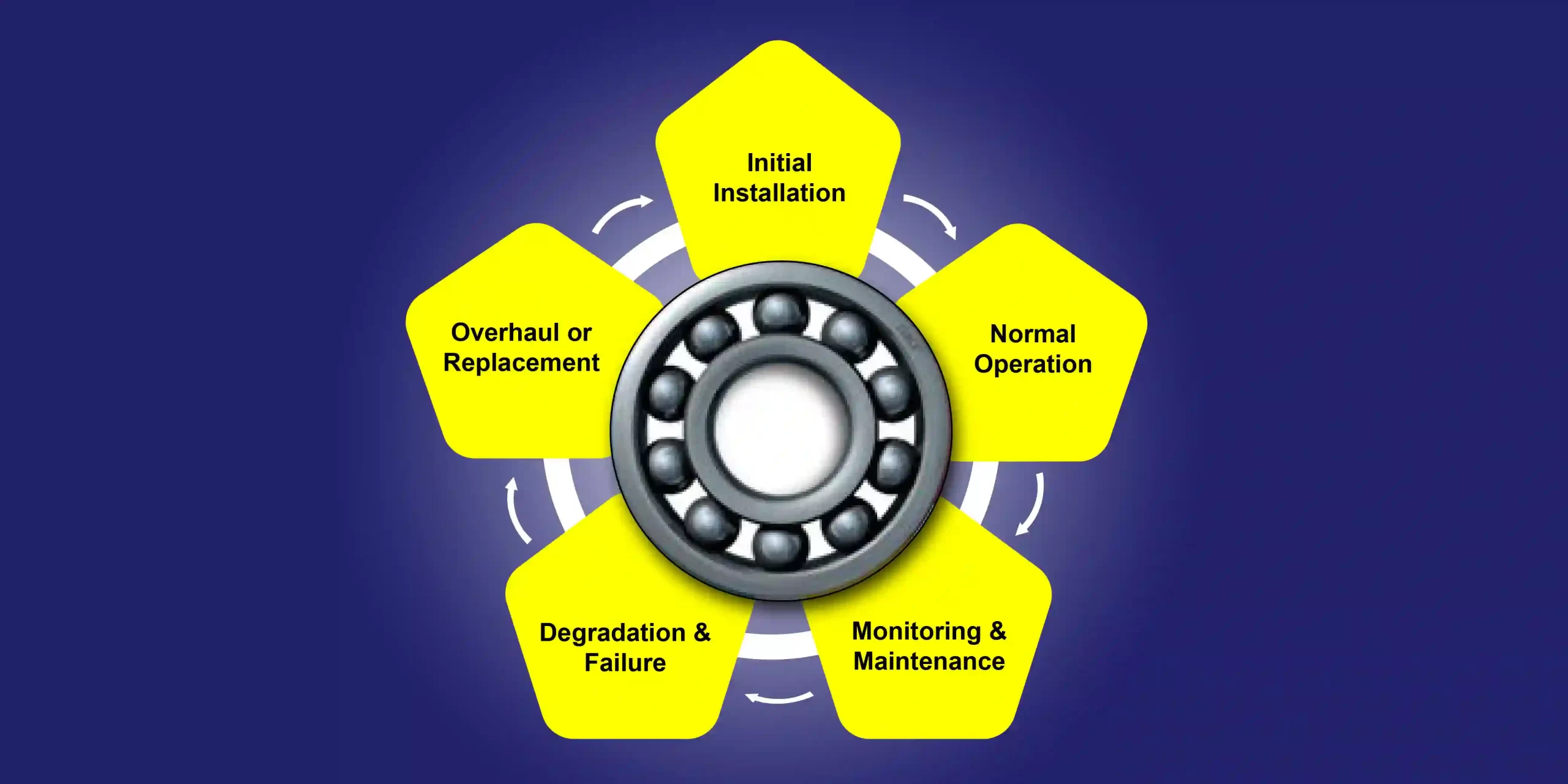

Stages of a Bearing's Life

- Initial Installation: The bearing is installed into the machinery, undergoes initial break-in, and begins its operational life.

- Normal Operation: During this stage, the bearing performs its intended function, experiencing regular loads, speeds, and operating conditions.

- Monitoring and Maintenance: Regular monitoring of bearing performance and scheduled maintenance routines are carried out to ensure optimal operation and detect any potential issues early on.

- Degradation and Failure: Over time, the bearing may start to exhibit signs of wear, fatigue, or damage, eventually leading to failure if not addressed promptly.

- Overhaul or Replacement: Depending on the extent of damage or wear, the bearing may undergo overhaul or replacement to restore functionality and prevent further damage to the machinery.

Factors Affecting Bearing Life

Several factors can influence the life expectancy of bearings, including:

- Operating conditions (e.g., speed, load, temperature)

- Lubrication quality and frequency

- Installation and alignment accuracy

- Contamination levels (e.g., dust, debris, moisture)

- Maintenance practices and intervals

- Prototype & Testing

Before bearings are mass-produced, they undergo rigorous prototyping and testing phases to ensure they meet performance and reliability standards. This involves simulated operational testing, material analysis, and quality control checks to identify any potential weaknesses or areas for improvement.

Overhauls and Replacements: Knowing When It's The Right Time

Determining the right time for overhauls or replacements depends on various factors, including:

- Monitoring data (e.g., vibration analysis, temperature monitoring)

- Visual inspection of the bearing and surrounding components

- Historical performance data and maintenance records

- Manufacturer recommendations and industry best practices

Ideal Lifespan for an Industrial Bearing?

The lifespan of an industrial bearing can vary significantly depending on factors such as operating conditions, maintenance practices, and the quality of the bearing itself. However, with proper care and maintenance, industrial bearings can typically last for several years in demanding applications.

How to extend bearing life? To extend the life of bearings, it’s essential to:

- Ensure proper installation, alignment, and lubrication

- Monitor operating conditions regularly and address any issues promptly

- Implement a proactive maintenance routine, including inspections, lubrication, and condition monitoring

- Choose high-quality bearings suitable for the specific application and operating environment

Most Common Signs of Bearing Failure

The best way to extend bearing life is by reading the warning signs ahead of time to avoid sudden failure. Some common signs of bearing failure include:

- Unusual noise or vibration coming from the bearing or machinery

- Increased operating temperature

- Excessive play or movement in the bearing

- Visible signs of wear, corrosion, or damage

- Sudden changes in performance or efficiency

FAQ's

What factors influence the design of bearings during the manufacturing phase?

Factors such as load capacity, speed, operating temperature, lubrication requirements, and environmental conditions influence the design of bearings during the manufacturing phase to ensure optimal performance and reliability in various applications.

How can I monitor the operational conditions of bearings?

Operational conditions of bearings can be monitored using various techniques, including vibration analysis, temperature monitoring, oil analysis, and visual inspections, to detect early signs of wear, damage, or abnormal behavior.

How often should bearings undergo maintenance, and what does a maintenance routine typically involve?

The frequency of bearing maintenance depends on factors such as operating conditions, load, speed, and manufacturer recommendations. A typical maintenance routine may include inspections, lubrication, cleaning, and condition monitoring at regular intervals.

When is the right time to consider overhauls or replacements for bearings?

Overhauls or replacements for bearings should be considered when they show signs of wear, damage, or degradation beyond acceptable limits, as determined by monitoring data, visual inspections, and manufacturer recommendations.

Can a bearing be re-used after its initial service?

In some cases, bearings can be re-used after their initial service if they pass thorough inspection and testing for wear, damage, and dimensional accuracy. However, it’s essential to follow manufacturer guidelines and industry best practices to ensure safety and reliability.