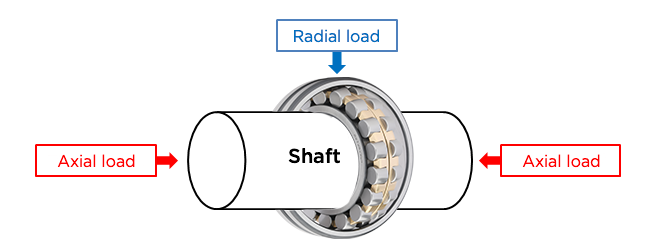

In the intricate world of bearings and mechanical systems, the concepts of axial load and radial load play a pivotal role in ensuring smooth operation, durability, and overall performance. Let us understand the concepts by deep diving into the basics and applications.

What is an Axial load?

Concept: Axial load, also known as thrust load, is a force applied parallel to the axis of a mechanical component or bearing. It tends to move components along the axis, either towards or away from the source of the force. The pushing or pulling a component in a straight line is the simplest example of an axial load.

Example 1: Elevator in a skyscraper. The cables that bear the weight of the elevator unit are bearing axial loads. As the elevator moves up or down, the cables must withstand the thrust forces generated by the changing load due to gravity.

Example 2: Hydraulic press in a manufacturing unit. Thrust bearings in the hydraulic cylinder are exposed to axial loads, ensuring controlled movements and precise shaping of materials.

Components: Here are some of the components which are capable of bearing an axial load.

- Thrust Bearings: Designed to withstand axial loads it specialises in ensuring controlled movement along the axis.

- Screws and Bolts: Fasteners like screws and bolts often experience axial loads, especially in applications where tension or compression forces are prevalent.

Applications: Here are some of the scenarios where you will find axial load being applied:

- Automotives: In automotive applications, axial loads are managed by thrust bearings, which ensure stable and controlled motion during acceleration and deceleration.

- Aerospace Engineering: Aircraft components, such as control surfaces and landing gear, experience axial loads during takeoff, landing, and manoeuvres.

What is a Radial Load?

Concept: Radial load is the force applied perpendicular to the axis of a mechanical component or bearing. It works perpendicular to the axis, aiming to compress or deform the component radially. The force experienced by a wheel rolling on a surface is an example of radial load.

Example 1:

Conveyor belt system in a manufacturing plant: The rollers which support the belt are bearing the radial loads due to the weight of the material transported. Bearings help ensure that these rollers rotate smoothly, while maintaining the efficiency of the conveyor system.

Example 2:

Heavy machinery gearbox: Cylindrical roller bearings in a gearbox manage radial loads. These help maintain a smooth rotation of gears when the force is acting perpendicular to the shaft.

Components:

- Roller Bearings: Cylindrical or tapered roller bearings are common components designed to handle radial loads efficiently.

- Bushings: In mechanical systems, these are used to support radial loads and keep friction to minimum.

Applications: Here are some of the scenarios where you will find radial load being applied:

- Wheel Bearings in Vehicles: In wheel bearings, the force is exerted perpendicular to the axle, supporting the weight of the vehicle. Therefore this manages radial load. Electric Motors: Bearings in electric motors that require smooth rotations endure radial loads under the influence of gravitational forces.

Role of Loads in Bearings and Mechanical Components

| Role of Axial Loads in Bearings | Role of Radial Loads in Bearings |

| Thrust Bearings specifically handle axial loads, to prevent mechanical components from moving along the axis. | Deep Groove Ball Bearings are used for radial loads in applications like conveyor systems and electric motors. |

| Angular Contact Bearings are often used in pairs to manage both axial and radial loads. This is commonly found in applications like machine tool spindles. | Cylindrical Roller Bearings are ideal for high radial loads, often employed in heavy machinery and industrial equipment. |

How to Calculate Axial and Radial Loads?

|

Axial Load Calculation Formula |

Radial Load Calculation Formula |

|

F = P × D Axial Where, F denotes axial load Axial P denotes thrust force, D denotes the effective diameter of the component |

F = P × C Radial Where, F denotes the radial load, Radial P denotes the thrust force, C denotes dynamic load capacity of the bearing. |

When it comes to operating industrial machinery, axial and radial loads are not just technical nuances but practical determinants of operational efficiency.

Understanding the dynamics of axial and radial loads are:

- Fundamental in crafting machinery for precision and durability of operations

- Understanding how to handle and operate heavy-duty equipment for seamless performance

- Necessary to ensure reliable performance, enhanced efficiency and prolonged machinery life in the industrial landscape

To help optimise your machinery and equipment performance, reach out to our experts today!