Basic Bearing Technology Training

- Delivered by Industry Experts

- Mode of training: Onsite at NBC Bearings

- Duration: 2 to 3 days

If your interest lies in understanding bearing technology then the ideal training course for you is our Basic Bearing Technology Training. In this exclusive 3 day training program, you will learn about the latest inputs in bearings technology, technical know-how on bearings and its technology, components, classifications & nomenclature, drawing, bearing loads, seals, lubrication, fatigue, bearing life and finally its applications.

Curriculum

- Bearing basics

- Ball and roller bearing used for rotating equipment

- Bearing designations

- Bearing arrangements

- Factors affecting Bearing service life

- Lubrication practices

- Mounting and dismounting guidelines and shaft condition

- Need of bearing damage analysis

- How to perform ‘Bearing Damage Analysis’

- Making a RCFA report

- New solutions

Enroll Now !

Product knowledge

Bearing Basics

Technical knowledge and expertise about bearings and their technology, components, types & nomenclature, drawing, bearing loads, seals, lubrication, fatigue, bearing life, and application.

Angular Contact Ball Bearing

focus on features and benefits of single-row and double-row angular contact ball bearings. The arrangement of universally matchable angular contact ball bearings is also discussed. Four-point contact ball bearings are also considered.

Tapered Roller Bearing

This course describes the construction and features of the NBC range of tapered roller bearings. Typical applications for these bearings are discussed, and the user will be able to identify an NBC tapered roller bearing by its designation.

Deep Groove Ball Bearing

This course will cover the designation and NBC product range. In addition, you will also learn about the bearing applications, failure, mounting, and dismounting methods.

Lubrication

In this course, you will learn about the science behind the usage of lubricants and their role in bearing. Furthermore, features and benefits of NEI standard bearing greases will be outlined, and you will learn about the know-how of selecting the grease for a specific application.

Cage, Seal, And Shield

In this course, you will learn about the cage, seal design and construction, material, and selection criteria.

Condition Based Monitoring

Vibration Basics

Introduction to Basic Vibrations starts with the fundamental principle of vibrations with a single and double degree of freedom systems. These fundamental vibration systems provide a solid platform to understand general vibrations and apply or use them in simple mechanical problems.

Thermography Basics

This online class covers the theory, equipment, and applications of infrared thermography in condition monitoring, quality assurance, building envelope, and nondestructive testing of materials fields.

Lubrication Management

A course providing basic training in industrial lubricants and oil sample-taking machinery.

Proactive Maintenance

Bearing Mounting and Dismounting

This course introduces rolling element bearings, ways of mounting and dismounting different types of bearings, their maintenance, and analysis of defects. With hands-on training, audio-visuals, lectures, and discussion opportunities, this course delivers critical information on installing and maintaining rolling element bearings in rotating machinery.

Bearing Damage Classification

The course objective is to provide background and methodology for analyzing failed and damaged bearings (due to noise, heat, vibration, etc.) and their components. You will understand the root causes of bearing damage, failures, and reason that can reduce the service life.

What will you learn – Basic understanding of different types of bearings, Nomenclature, Do’s & Don’ts of bearing handling, bearing storage, etc.

Most beneficial for – Anyone who wants to enhances their bearing knowledge. Members from Manufacturing, R&D, Quality, Purchase, Sales, Marketing and Maintenance departments

What will you learn – Bearing Maintenance practices – Mounting & Dismounting, Lubrication, Fits & Tolerances

Most beneficial for – Members from Maintenance, Services and Warranty teams.

What will you learn – Different types of failure modes and corrective actions. Hands on experience with different failed samples

Most beneficial for – Member from Maintenance, Services, Quality and Warranty teams

What will you learn – This is a customised program and the course content will be developed as per the requirement.

Target Industries – Automotive | Industrial | Railways

Most beneficial for – Members from R&D and Design teams

What will you learn – Fundamentals of predictive maintenance. Topics include Vibration analysis, Thermography, Alignment, Balancing etc

Target Industries – Automotive | Industrial | Railways

Most beneficial for – Members from Maintenance teams.

An initiative to upgrade the skills of mechanics/apprentices. Hundreds of attendees have acquired basic bearing knowledge on several topics in short one-hour sessions provided free of cost. Join our mailing list to know the details of our upcoming sessions.

To explore the SuperMech sessions, visit NBC SuperMech Workshops

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

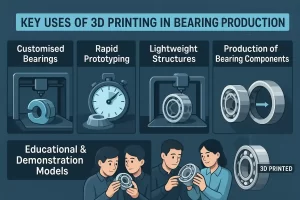

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

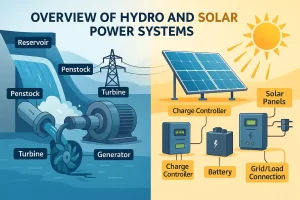

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

The Critical Role of Bearings in Drones and UAVs

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Request more information

Leadership quotes