Design of Angular Contact Ball Bearings

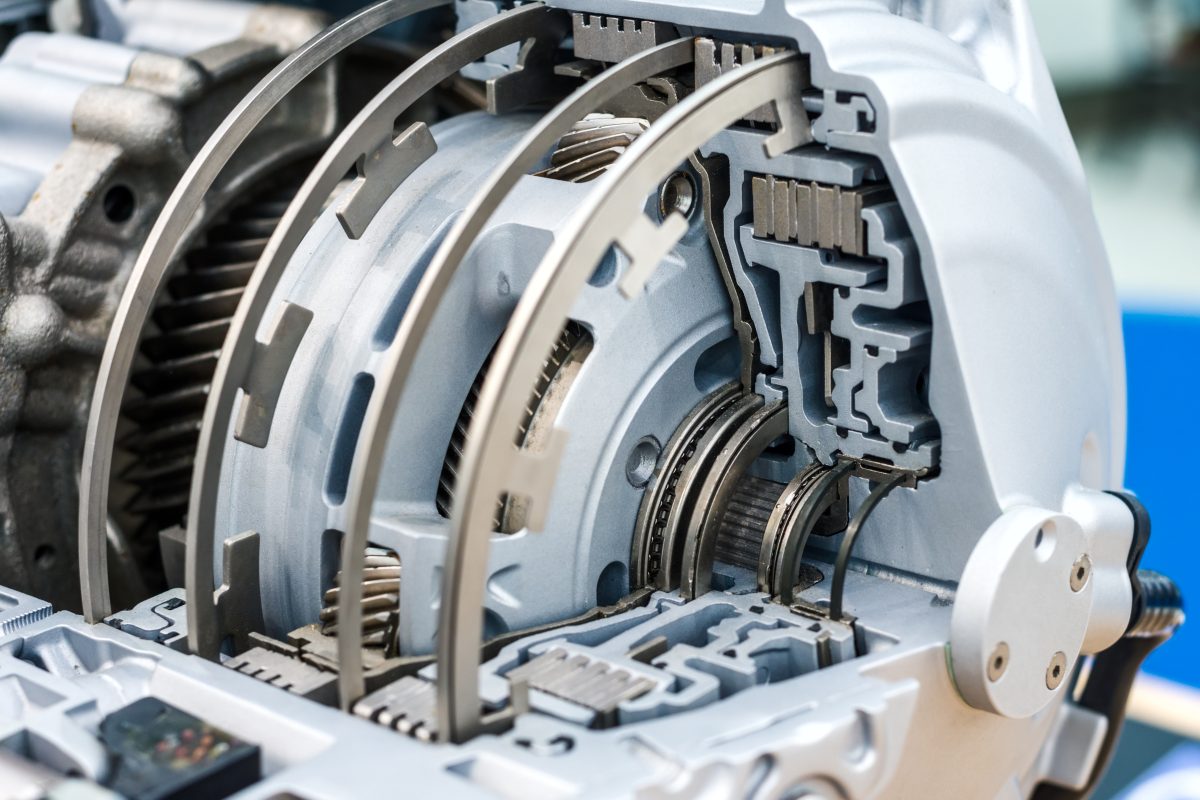

These Bearings are designed with high precision and standards to fit aptly to various high-load applications. In terms of design, it consists of the cage, ring, and ball material. They have a contact angle of around 15 degrees and 25 degrees as compared to radial bearings which only have a contact angle of 8 degrees, this makes up for accommodating tilting movements. The other factor is that the design of angular contact ball bearings features one raised shoulder on the outer ring which makes it apt for faster speed and higher loads.What do you mean by Angular Contact Ball Bearings?

Angular contact ball bearings are bearings that have balls in them that make contact with the inner and outer races at an angle. The angle of contact creates a “point contact” between the balls and the races, rather than the flat contact found in standard ball bearings. This design helps to increase the bearing’s capacity for carrying radial and thrust loads. The heavy carrying capacity makes it a perfect fit in many industries without any problem.What is the importance of Angular Contact Ball Bearings?

Angular contact ball bearings are an important type of bearing used in a wide variety of applications. They are typically used in applications where there is a need for high precision and high load capacity. Also, these bearings are used in applications where there is a need for low friction and low noise.Benefits of Angular Contact Ball Bearing

There are many benefits of using ball bearings. Some of the benefits include:- Increased durability: These bearings are designed to withstand high loads. The balls in the bearing are separated by a metal cage, which helps to evenly distribute the load and prevent the balls from coming into contact with each other. This results in a more durable bearing that can withstand higher loads for longer periods.

- Reduced friction: These types of bearings have lower friction than other types of bearings. This is due to the way the balls are separated by the metal cage. The cage helps to reduce the amount of contact between the balls and the bearing surface, which reduces friction.

- Improved efficiency: These bearings are more efficient than other types of bearings because they have less friction. This means that they require less energy to operate, which can lead to savings in both energy and operating costs.

- Requires Less Axial Space: In such arrangements where there is limited axial space, it can fit in well without using multiple bearings.

- Designed for High Rigidity: Best to be used in those use cases where High Rigidity and Precision are the utmost priority.

What are the uses of Angular Contact Ball Bearings?

These bearings have balls in them that make contact with the inner and outer raceways at a point on the bearing. These bearings can support high radial loads and high axial loads. They are usually used in pairs so that they can cancel out any forces that may act on the bearing. These Ball Bearings are used in many different applications such as electric motors, pumps, fans, gearboxes, and compressors. Some common use cases are:- To support high radial loads in applications such as electric motors and gearboxes

- To support high axial loads in applications such as compressors and pumps

- To cancel out any forces that may act on the bearing when used in pairs