Industrial

Solutions for Cement manufacturers

NBC has wide range of bearings to support Cement Industry. Our strong customer focus makes us a preferred choice for various applications. NBC bearings provides long service life under the most challenging environment for various equipment of Cement Industry.

Cement producers depend upon continuous production with minimum down time in extreme environment. Bearings are developed with special heat treatment process, material and optimized cage design for various applications. Our advanced heat treatment and manufacturing processes enable us to supply bearings which are most reliable , dependable and cost effective for Cement industry in various applications such as

Bearing Applications

- Conveyor system

- Crushers

- Vibratory feeders & screens

- Vertical mills

- Roller press

- Gear boxes & drives

- Fans

Features

- Bearings with high load carrying capability to enhance fatigue life.

- Special tolerance class and limiting speed

- Optimized internal design and roller crowning to compensate misalignment during operation

- Case carburized bearings for better performance under shock loads

- Ready to assemble Pre-set bearings with controlled tolerances and bench end play (BEP)

Download Cement Catalogue

Mostly Used Bearings

Our Offerings

NBC manufactures over 200 million bearings each year offered in 2300+ variants to serve the customers in Automotive, Railway, Aerospace and Industrial segments. Product range includes ball bearings, taper roller bearings, cylindrical bearings, spherical roller bearings, needle roller bearings, railway axle boxes and other special products.Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

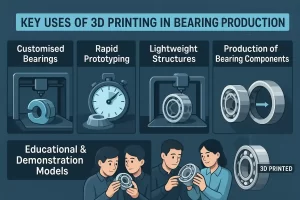

The Role of 3D Printing in Modern Bearing Production

The manufacturing landscape is an ever-evolving space driven by advances in production technology, machine tools, information technology, materials, and products. One of the newest advancements

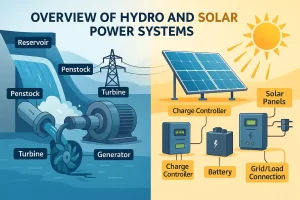

How Bearings Improve Performance in Hydro & Solar Power Systems

Most of us are aware that bearings are important components used in various mechanical setups, vehicles, household appliances, and more. However, bearings are also proving

The Critical Role of Bearings in Drones and UAVs

We have always heard – bearings are a vital component of industrial machinery, motors, and engines, utilised to minimise friction and allow for smooth rotation.

Request more information

Leadership quotes