About Us

Research & Development

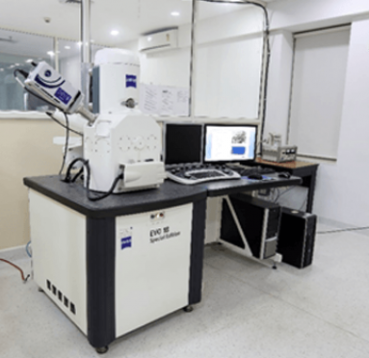

Excellence in R&D is driven by providing innovative and effective technology responses to help develop the right products. Our superior innovative design & manufacturing capabilities and product development combined with a flexible approach in addressing market challenges supporting larger nation-wide initiatives like Digitization, Care for the environment, resource conservation, etc.

Main product innovation focus areas based on market drivers are,

- Bearings for Electric Vehicle with high speed, low friction, and low noise feature to fulfill the EV customer’s expectations.

- Smart Bearing solutions with sensors

- Reliability Improvement solutions, with an improved service life of current and new products

- Fuel efficiency solutions provide fuel-saving and help in meeting Emission Regulations at the customer end

- Develop networking with key stakeholders at multiple verticals

- Online sessions & Discussion with customer teams- Technology days, workshops, etc

- Problem solving project with customers

- Early engagement with customers – Partnership project initiation Scheduled meeting with customer at multiple levels with NBC leaderships

- Weekly meetings with customers based on project needs

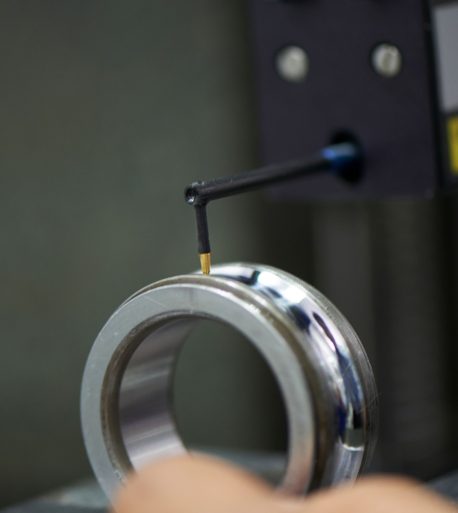

New Product Development

In an era of shorter product lifecycle and looking into the aggression of customers to launch new and advanced products to sustain the competitive global market, we at NBC Bearings are continually working hand in hand with our customers to develop products at a faster pace and increasing the no. of products developed in a year in arithmetic progression.

To sustain customer aggression, we are not only continuously updating our product development infrastructure but also updating system infrastructure, with an eye towards Industry 4.0.

Our above customer centric approach is continuously increasing confidence of our customers as a dependable and sustainable supplier.

Patents and Publications

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight,industry trends, tip news headlines.

Importance of Bearing Clearance: Unveiling the Critical Dimension

Bearing clearance plays a pivotal role in ensuring optimal functionality, longevity, and efficiency of its applications. Let us understand the significance of bearing clearance, exploring

Importance of Precision in Bearing Manufacturing

The Impact of Precision on Energy Efficiency In industrial machinery and equipment, precision is not just a desirable trait but a fundamental necessity. Nowhere is

A Relentless Pursuit of Perfect in Motion

Experience the future of mechanical engineering with smart bearings, precision technology, and eco-friendly solutions. Evolution in motion.

Request more information

Leadership quotes